Product Description

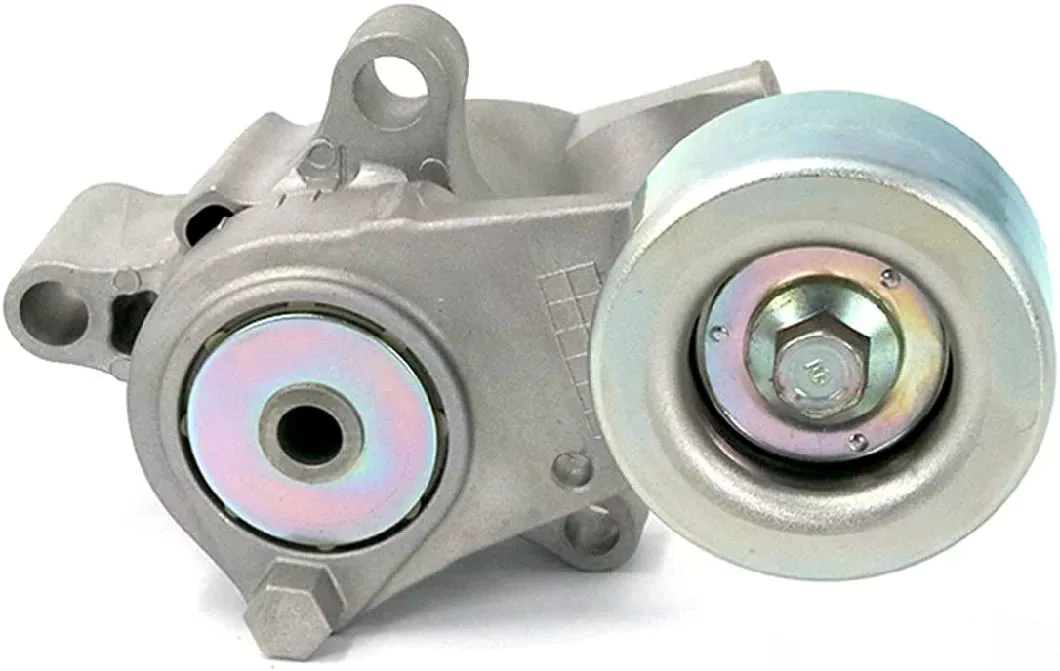

Japanese Car Timing Chain Parts 16620-31040 Belt Tensioner Pulley

Product Specification:

| OEM No: | 16620-31040 |

| Apply To: |

For car |

| Brand: | FENGMING |

| Condition: | Brand New |

| Stock Availability: | Yes |

| Minimum Order QTY | 1PC |

| OEM Order Acceptability: | Yes |

| Small order Lead Time: | 3-7 days |

| Large Order Lead Time: | 15-30 days |

| Quality Warranty | 12 months |

| PACKAGING | As neutral or as customer’s request, FENG MING PACKING |

| Payment Methods: | Paypal, Western Union, Bank T/T, L/C |

| Shipment Methods: | DHL, UPS, TNT, FedEx, Aramex, EMS, Air Cargo, Sea Cargo |

| Car Make: | Car |

|---|---|

| Car Model: | Car |

| Part Number: | Tensioner Pulley |

| Quality: | 100% |

| MOQ: | 1PC |

| Delivery Time: | Within 2-5 Working Days |

| Samples: |

US$ 19/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

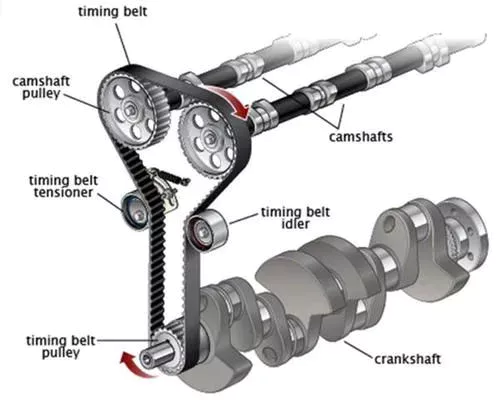

What are the reliability and durability aspects of drive belt tensioners in ensuring consistent tension?

Reliability and durability are crucial aspects of drive belt tensioners in ensuring consistent tension within a vehicle’s belt system. Drive belt tensioners play a vital role in maintaining the proper tension of the drive belt, which is essential for reliable power transmission and preventing belt slippage. Here’s a detailed explanation of the reliability and durability aspects of drive belt tensioners in ensuring consistent tension:

- Material Selection:

- Design and Engineering:

- Load and Tension Capacity:

- Resistance to Environmental Factors:

- Maintenance and Service Life:

The choice of materials used in manufacturing drive belt tensioners significantly impacts their reliability and durability. Tensioners are typically constructed using high-strength materials such as steel, aluminum, or reinforced polymers. These materials provide the necessary strength, rigidity, and resistance to wear and fatigue. The selected materials should be able to withstand the forces and loads experienced during operation without deformation or premature failure, ensuring long-term reliability and consistent tensioning performance.

The design and engineering of drive belt tensioners are critical factors in ensuring their reliability and durability. Tensioners need to be designed to accommodate the specific requirements of the belt system and driven components. This includes considerations such as belt routing, tensioner mounting, and the integration of features like pulleys, bearings, and damping mechanisms. Well-designed tensioners undergo rigorous testing and analysis to ensure they can withstand the anticipated loads, vibrations, temperature variations, and other operating conditions. Proper engineering practices contribute to the longevity and consistent performance of the tensioner throughout its service life.

Reliability and durability of drive belt tensioners are closely linked to their load and tension capacity. Tensioners must be capable of applying and maintaining the proper tension on the drive belt, ensuring it remains properly engaged with the pulleys. The tensioner should be designed with a suitable load capacity to handle the anticipated forces and loads imposed on the belt system during various operating conditions. Adequate load and tension capacity prevent excessive belt deflection, slippage, or premature wear, ensuring consistent tension and reliable power transmission.

Drive belt tensioners are exposed to various environmental factors that can impact their reliability and durability. Factors such as temperature variations, moisture, dirt, and chemical exposure can affect the performance and lifespan of the tensioner. To ensure consistent tension, tensioners are often designed with protective coatings, seals, or materials that offer resistance to these environmental elements. Proper sealing and corrosion-resistant materials minimize the risk of contamination or degradation, ensuring the tensioner’s long-term reliability and consistent tensioning capability.

Regular maintenance and adherence to recommended service intervals are essential for preserving the reliability and durability of drive belt tensioners. Tensioners should be inspected periodically for signs of wear, damage, or misalignment. Proper lubrication of moving parts, such as pulleys and bearings, is also crucial for their longevity and consistent performance. Following the manufacturer’s recommended maintenance procedures and replacing worn or damaged tensioners in a timely manner helps ensure that the tensioner maintains its reliability and consistent tensioning function throughout its expected service life.

In summary, the reliability and durability aspects of drive belt tensioners are crucial in ensuring consistent tension within a vehicle’s belt system. Material selection, design and engineering practices, load and tension capacity, resistance to environmental factors, and proper maintenance all contribute to the reliability and longevity of tensioners. By choosing well-designed and properly maintained tensioners, automotive systems can benefit from consistent belt tension, reliable power transmission, and minimized risks of belt slippage or failure.

How do drive belt tensioners contribute to reducing wear and increasing the efficiency of power transmission in vehicles?

Drive belt tensioners play a critical role in reducing wear and increasing the efficiency of power transmission in vehicles. They are designed to maintain proper tension on the drive belt, ensuring optimal contact with the pulleys and minimizing slippage. Here’s a detailed explanation of how drive belt tensioners contribute to reducing wear and increasing the efficiency of power transmission:

- Optimal Belt Tension:

- Preventing Belt Slippage:

- Reducing Belt Wear:

- Efficient Power Transfer:

- Minimizing System Stress:

Drive belt tensioners are responsible for maintaining the optimal tension of the drive belt. They apply the correct amount of force to keep the belt tight against the pulleys. When the tensioner is functioning properly, it ensures that the belt remains in constant contact with the pulleys, preventing slippage. This optimal tensioning reduces wear on the belt and associated components, such as the pulleys and bearings, by minimizing unnecessary friction and heat generation.

Slippage occurs when the drive belt loses traction and slips on the pulleys. This can happen when the tension on the belt is insufficient. A properly functioning tensioner prevents belt slippage by maintaining the appropriate tension throughout the operating range of the engine. By ensuring a secure grip on the pulleys, the tensioner eliminates slippage-related issues, such as decreased power delivery, reduced efficiency, and accelerated wear on the belt and pulleys.

Drive belt tensioners contribute to reducing belt wear by maintaining the correct tension. When the tensioner applies the optimal amount of force, the belt remains properly aligned and engaged with the pulleys. This alignment reduces side loading and excessive bending of the belt, which can cause premature wear. By minimizing belt wear, the tensioner helps extend the lifespan of the belt, reducing the frequency of belt replacements and associated maintenance costs.

A properly tensioned drive belt ensures efficient power transfer from the engine to various driven components, such as the alternator, power steering pump, air conditioning compressor, and water pump. When the tensioner maintains the correct tension, the belt transmits power smoothly and effectively. This allows the driven components to operate at their intended speed and capacity, maximizing their efficiency and performance. Efficient power transmission reduces energy losses, enhances overall vehicle efficiency, and optimizes fuel consumption.

By maintaining proper tension, drive belt tensioners help minimize stress on the belt system and associated components. When the tensioner ensures the optimal tension of the belt, it reduces unnecessary strain on the belt, pulleys, bearings, and other components. This minimizes the risk of premature component failure, prolongs their lifespan, and improves system reliability. By reducing system stress, the tensioner contributes to the overall durability and longevity of the power transmission system in vehicles.

In summary, drive belt tensioners contribute to reducing wear and increasing the efficiency of power transmission in vehicles by maintaining optimal belt tension, preventing slippage, reducing belt wear, enabling efficient power transfer, and minimizing system stress. Proper tensioning ensures reliable operation, extends the lifespan of the belt and associated components, and maximizes the overall performance and efficiency of the power transmission system in automotive applications.

Can you describe the various types of drive belt tensioners, such as automatic or spring-loaded tensioners?

Drive belt tensioners come in various types, each with its own design and mechanism for maintaining belt tension. These types include automatic tensioners, spring-loaded tensioners, and hydraulic or dampened tensioners. Here’s a detailed description of each type:

- Automatic Tensioners:

- Spring-Loaded Tensioners:

- Hydraulic or Dampened Tensioners:

Automatic tensioners are commonly used in modern automotive systems. They utilize a combination of mechanical components and springs to automatically adjust and maintain the proper tension in the drive belt. Automatic tensioners typically consist of a spring-loaded arm or pulley that applies tension to the belt. As the belt stretches due to wear or temperature changes, the tensioner compensates by applying more force, ensuring optimal tension at all times. The automatic tension adjustment feature of these tensioners eliminates the need for manual adjustment and provides convenience and consistent belt tension.

Spring-loaded tensioners are another common type of drive belt tensioners. They rely solely on mechanical springs to apply and maintain tension in the drive belt. Spring-loaded tensioners consist of a pulley mounted on an arm that is loaded with a strong spring. The spring applies a specific amount of force to the pulley, which in turn maintains tension in the belt. These tensioners usually have a fixed tension setting determined by the design of the spring, and manual adjustment is typically not required. Spring-loaded tensioners are widely used in various automotive applications and provide consistent tension over time.

Hydraulic or dampened tensioners are a type of tensioner that utilizes hydraulic fluid or a dampening mechanism to maintain belt tension. These tensioners often consist of a pulley connected to a hydraulic cylinder or a dampening mechanism such as a torsion bar. The hydraulic or dampening mechanism allows for controlled movement of the pulley, absorbing vibrations and fluctuations in the belt tension. This type of tensioner provides smoother operation, reduces noise, and prolongs the life of the belt and associated components. Hydraulic or dampened tensioners are commonly used in applications where noise and vibration reduction are important, such as in luxury vehicles.

In summary, there are several types of drive belt tensioners, including automatic tensioners, spring-loaded tensioners, and hydraulic or dampened tensioners. Automatic tensioners use mechanical components and springs to automatically adjust belt tension, spring-loaded tensioners rely on mechanical springs for tension maintenance, and hydraulic or dampened tensioners utilize hydraulic or dampening mechanisms to provide smoother operation and reduce noise. The choice of tensioner type depends on the specific application, performance requirements, and design considerations of the automotive system.

editor by CX 2023-11-13

China X5 Belt Tensioner Pulley for E70 11287542887 with Hot selling

Merchandise Description

Item Description

| Merchandise identify | belt tensioner pulley |

| OE amount | |

| Top quality | OE normal |

| Fits for |

X5 Series |

| Software | Auto cooling parts |

| Package | Model, neutral or tailored package deal |

| Port | HangZhou |

| Payment | T/T, Western Union, PayPal, Trade Assurance |

| MOQ | one piece |

Packaging & Shipping and delivery

| With inventory… | three-7 days |

| Without having stock… | 7-15 days |

| Delivery | Sea, air, specific, and so on. |

| Shipping Time period | EXW HangZhou |

We supply components for…

| 3 series | E30 E36 E46 E90 F30 F35 | C-Course | W202 W203 W204 | |||

| five Collection | E34 E39 E60 F10 F18 | E-Course | W124 W210 W211 W212 | |||

| seven Collection | E32 E38 E65/E66 F01 F02 | GL | X164 X204 | |||

| X1 | E84 | ML | W163 W164 | |||

| X3 | E83 F25 | R | W251 V251 | |||

| X5 | E53 E70 | S | W140 W220 W221 | |||

| Gasket | Cylinder Head | Oil Seal | Air Filter | |||

| Fuel Filter | Air Mass Meter | Belt | Starter | |||

| Engine Mount | Belt Tensioner | Radiator Fan |

Expansion Valve | |||

| Ignition Coil | Tie Rod Conclude | Water Pump | Thermostat | |||

| Shock Absorber | Power Steering Pump | Oxygen Sensor | Stabilizer Website link | |||

| Oil Pump | Solenoid Valve | Axle Rod | Boll Joint | |||

| Drive shaft | Window Lifter | Wheel Bolt | Gas Spring | |||

Company Profile

Set up in 1994, HangZhou Ideal Auto Parts Co., Ltd. is a world-wide and professional supplier, concentrating on CZPT model vehicle parts, supplies chassis components and routine maintenance parts which match for German luxury autos. With much more than twenty five a long time co-procedure with mend stores, distributors, brokers and manufactures, we have developed our world-wide producing normal and income network over the globe. Originated from Germany, CZPT adheres to the spirit of craftsmanship, offering safe, higher quality and trusted vehicle components. We believe that we must shoulder the duty and mission on revitalizing Chinese national automotive components industry, and make CZPT popular in the globe.

Certifications

FAQ

Q1: What is actually your advantages?

1. Sensible price tag and trustworthy quality

2. Two many years or 60,000 kilometers warranty (For chassis areas only, you should request for the assortment)

3. Satisfying and swift right after-sale service

4. Rapid and protected modes of payment

5. Ships things timely and speedily.

Q2: To which areas have you exported?

Africa, South The usa, Asia, middle east and so on.

Q3: What items you promote proper now?

1. Suspension areas sequence

2. Brake program parts collection

3. Motor cooling parts sequence

4. Electronic areas series

5. Steering components and backlinks collection

6. Push shaft sequence

7. Oil and gas series (Filters, pumps, and so on.)

8. Mounting parts sequence (Engine mount, transmission mount, and so on.)

Q4: How to assure the top quality of your product?

1. Rigid inspection for the duration of generation

two. Recheck the items before cargo

three. Monitor and acquire comments from our clients.

Q5: How about your delivery time?

7-25 Days right after getting your payment.

|

US $17.59-21.59 / Piece | |

1 Piece (Min. Order) |

###

| Type: | Cooling System |

|---|---|

| Material: | Plastic |

| Deck: | Single |

| Warranty: | 12 Months |

| Transport Package: | Brand Package |

| Specification: | Same as OE |

###

| Customization: |

Available

|

|---|

###

| Product name | belt tensioner pulley |

| OE number | 1128 7542 887 |

| Quality | OE standard |

| Fits for |

X5 Series |

| Application | Auto cooling parts |

| Package | Brand, neutral or customized package |

| Port | Guangzhou |

| Payment | T/T, Western Union, PayPal, Trade Assurance |

| MOQ | 1 piece |

###

| With stock… | 3-7 days |

| Without stock… | 7-15 days |

| Shipping | Sea, air, express, etc. |

| Shipping Term | EXW Guangzhou |

###

| 3 series | E30 E36 E46 E90 F30 F35 | C-Class | W202 W203 W204 | |||

| 5 Series | E34 E39 E60 F10 F18 | E-Class | W124 W210 W211 W212 | |||

| 7 Series | E32 E38 E65/E66 F01 F02 | GL | X164 X204 | |||

| X1 | E84 | ML | W163 W164 | |||

| X3 | E83 F25 | R | W251 V251 | |||

| X5 | E53 E70 | S | W140 W220 W221 | |||

| Gasket | Cylinder Head | Oil Seal | Air Filter | |||

| Fuel Filter | Air Mass Meter | Belt | Starter | |||

| Engine Mount | Belt Tensioner | Radiator Fan |

Expansion Valve | |||

| Ignition Coil | Tie Rod End | Water Pump | Thermostat | |||

| Shock Absorber | Power Steering Pump | Oxygen Sensor | Stabilizer Link | |||

| Oil Pump | Solenoid Valve | Axle Rod | Boll Joint | |||

| Drive shaft | Window Lifter | Wheel Bolt | Gas Spring | |||

|

US $17.59-21.59 / Piece | |

1 Piece (Min. Order) |

###

| Type: | Cooling System |

|---|---|

| Material: | Plastic |

| Deck: | Single |

| Warranty: | 12 Months |

| Transport Package: | Brand Package |

| Specification: | Same as OE |

###

| Customization: |

Available

|

|---|

###

| Product name | belt tensioner pulley |

| OE number | 1128 7542 887 |

| Quality | OE standard |

| Fits for |

X5 Series |

| Application | Auto cooling parts |

| Package | Brand, neutral or customized package |

| Port | Guangzhou |

| Payment | T/T, Western Union, PayPal, Trade Assurance |

| MOQ | 1 piece |

###

| With stock… | 3-7 days |

| Without stock… | 7-15 days |

| Shipping | Sea, air, express, etc. |

| Shipping Term | EXW Guangzhou |

###

| 3 series | E30 E36 E46 E90 F30 F35 | C-Class | W202 W203 W204 | |||

| 5 Series | E34 E39 E60 F10 F18 | E-Class | W124 W210 W211 W212 | |||

| 7 Series | E32 E38 E65/E66 F01 F02 | GL | X164 X204 | |||

| X1 | E84 | ML | W163 W164 | |||

| X3 | E83 F25 | R | W251 V251 | |||

| X5 | E53 E70 | S | W140 W220 W221 | |||

| Gasket | Cylinder Head | Oil Seal | Air Filter | |||

| Fuel Filter | Air Mass Meter | Belt | Starter | |||

| Engine Mount | Belt Tensioner | Radiator Fan |

Expansion Valve | |||

| Ignition Coil | Tie Rod End | Water Pump | Thermostat | |||

| Shock Absorber | Power Steering Pump | Oxygen Sensor | Stabilizer Link | |||

| Oil Pump | Solenoid Valve | Axle Rod | Boll Joint | |||

| Drive shaft | Window Lifter | Wheel Bolt | Gas Spring | |||

The importance of pulleys

A pulley is a wheel that rides on an axle or axle. The purpose of the pulley is to change the direction of the tensioning cable. The cable then transfers the power from the shaft to the pulley. This article explains the importance of pulleys and demonstrates several different uses for this machine. Also, see the Mechanical Advantages section below for the different types. let’s start.

simple machine

A simple pulley machine is a device used to transfer energy. It consists of a wheel with flexible material on the rim and a rope or chain tied to the other end. Then lift the load using the force applied to the other end. The mechanical advantage of this system is one, as the force applied to the load is the same as the force on the pulley shaft.

A simple pulley machine has many benefits, from the ability to build pyramids to building modern buildings with it. Pulleys are also popular with children because they can perform simple tasks such as lifting toys onto a slide, sliding them off the slide, and lifting them up again. These activities, called “transportation” by child development theorists, allow them to learn about the physics of simple machines in the process.

The mechanism works by using cables to transmit force. The cable is attached to one side of the pulley and the other side is pulled by the user. Lift the load by pulling on one end and the other end of the rope. Simple pulley machines have many commercial and everyday applications, including helping move large objects. They can be fixed or movable, and can be a combination of both. The present invention is a great tool for any beginner or engineer.

axis

The axle wheel is the basic mechanical part that amplifies the force. It may have originally appeared as a tool to lift buckets or heavy objects from a well. Its operation is demonstrated by large and small gears attached to the same shaft. When applied to an object, the force on the large gear F overcomes the force W on the pinion R. The ratio of these two forces is called the mechanical advantage.

The ideal mechanical advantage of shaft pulleys is their radius ratio. A large radius will result in a higher mechanical advantage than a small radius. A pulley is a wheel through which a rope or belt runs. Often the wheels are interconnected with cables or belts for added mechanical advantage. The number of support ropes depends on the desired mechanical advantage of the pulley.

In the design of the axle wheel, the axle is the fulcrum and the outer edge is the handle. In simple terms, wheels and axle pulleys are improved versions of levers. The axle pulley moves the load farther than the lever and connects to the load at the center of the axle. Shaft pulleys are versatile and widely used in construction.

rope or belt

Ropes or pulleys are mechanical devices used to move large masses. The rope supports a large mass and can be moved easily by applying a force equal to one quarter of the mass to the loose end. Quad pulleys have four wheels and provide the mechanical advantage of four wheels. It is often used in factories and workshops. It is also a popular choice in the construction industry. If you are installing a pulley in your vehicle, be sure to follow these simple installation instructions.

First, you need to understand the basics of how a rope or pulley works. The machine consists of one or more wheels that rotate on an axle. The rope or belt is wrapped around the pulley and the force exerted on the rope is spread around the pulley. It then transfers the force from one end of the rope to the other. The pulley system also helps reduce the force required to lift objects.

Another common rope or pulley is the differential pulley. This is similar to a rope pulley, but consists of two pulleys of different radii. The tension in the two halves of the rope supports half the load that the live pulley should carry. These two different types of pulleys are often used together in composite pulley systems.

Mechanical advantage

The mechanical advantage is the ratio of the force used to move the load through the pulley system to the force applied. It has been used to measure the effectiveness of pulley systems, but it also requires assumptions about applied forces and weights. In a simple 1:1 pulley system, the weight lifting the weight is the same as the weight of the person pulling the weight. Adding mechanical advantage can help make up for the lack of manpower.

This advantage stems from the mechanical properties of simple machines. It requires less force and takes up less space and time to accomplish the same task. The same effect can also be achieved by applying less force at a distance. Furthermore, this effect is called the output force ratio. The basic working principle of a pulley system is a rope with a fixed point at one end. The movable pulley can be moved with very little force to achieve the desired effect.

The load can be moved through the vertical entry using a simple pulley system. It can use a simple “pulley block” system with a 2:1 “ladder frame” or a 4:1 with dual pulleys. This can be combined with another simple pulley system to create a compound pulley system. In this case, a simple pulley system is pulling another pulley, giving it a 9:1 mechanical advantage.

Commonly used

You’ve probably seen pulley systems in your kitchen or laundry room. You probably already use it to hang clothes on an adjustable clothesline. You may have seen motor pulleys in the kitchens of commercial buildings. You might even have seen one on a crane. These machines use a pulley system to help them lift heavy loads. The same goes for theaters. Some pulleys are attached to the sides of the stage, enabling the operator to move up and down the stage.

Pulley systems have many uses in the oil and petroleum industry. For example, in the oil and gas industry, pulley systems are used to lay cables. They are arranged in a pulley structure to provide mechanical energy. When the rope is running, two pulleys are hung on the derrick to facilitate smooth running. In these applications, pulleys are very effective in lifting heavy objects.

A pulley is a simple mechanical device that converts mechanical energy into motion. Unlike chains, pulleys are designed to transfer power from one location to another. The force required to lift an object with a pulley is the same as that required by hand. It takes the same amount of force to lift a bucket of water, but it’s more comfortable to pull sideways. A bucket of water weighs the same as when lifted vertically, so it’s easy to see how this mechanism can be useful.

Safety Notice

When using pulleys, you should take several safety precautions to keep your employees and other workers on the job site safe. In addition to wearing a hard hat, you should also wear gloves to protect your hands. Using pulleys can lead to a variety of injuries, so it’s important to keep these precautions in mind before using pulleys. Here are some of the most common:

Pulleys are an important piece of equipment to have on hand when lifting heavy objects. Pulleys not only reduce the force required to lift an object, but also the direction of the force. This is especially important if you are lifting heavy objects, such as a lawn mower or motorcycle. Before starting, it is important to make sure that the anchoring system can support the full weight of the object you are lifting.

When using a pulley system, make sure the anchor points are adequate to support the load. Check with the pulley manufacturer to determine the weight it can safely lift. If the load is too large, composite pulleys can be used instead. For vertical lifts, you should use a sprocket set and wear personal protective equipment. Safety precautions when using pulleys are critical to worker health and safety.

editor by czh 2023-01-05

China Sinotruk HOWO Wechai Engine Tensioner Pulley 612600061754 with Great quality

Item Description

Solution Description

Sinotruk CZPT Wechai Motor Tensioner Pulley Vg260006571

We are specialized in the export of Vehicles spare Areas, located in the origin of CZPT ,HangZhou city,China. Largely deal in CZPT ,SHACMAN ,HINO, CAMC, XIHU (WEST LAKE) DIS.FENG CZPT motor,mixer truck , engineering machinery parts . we can generate unique cars in accordance to your requires.

Truck Human body and Human body Parts Components

| S/N | Products Range |

| 1 | Cab Human body ASSY, Locking Mechanism, Restricting Unit |

| two | Cab ground, Bumpers, Fender & Rear Fender, Air spring… |

| 3 | Taxi Door, Fog Light-weight, Sun Visor, Hydraulic Lock Assembly… |

| 4 | Steering Column, Entrance & Rear Glass, Wind-defend Wiper & washer… |

| five | Window, Roof Panel, Air Heater program… |

| six | Air Conditioner Program, Protection Belt, Take Electrical power Off… |

Electrical and Electronic Program

| S/N | Products Range |

| 1 | Battery, Car Horn, Regulator, Flasher, Relay… |

| two | Electric powered Equirments, Sensor, H2o Amount Buzzer… |

| 3 | Switch, Anti-theft Gadget, Sign Gadget, Motor meter… |

Motor Areas

| S/N | Products Range |

| 1 | Cylinder Head, Cylinder Liner, Crankshaft, Rod… |

| two | Piston, Piston Ring, Piston Pin, Piston Cooling Nozzle… |

| 3 | Oil Fitter, Gas Filter, Water Filter… |

| 4 | Oil Pump, H2o Pump, Injection Pump, Transfer Pump, turbo charger… |

| 5. | Primary bearing, con.rod bearing, fly wheel, fuel tank, overhaul fix gasket kit… |

Gearbox components

| S/N | Products Range |

| 1 | gearbox, Gearbox housing, prime cover, Main shaft, Principal shaft… |

| two | Countershaft, 2 / 3 equipment, 2nd speed gear(1/2/3/4/5… |

| 3 | reverse equipment ,clutch bearing and seat, synchronize assembly…. |

| four | synchronizer slider, synchronizer ring, gearbox shell…. |

| five | gearbox cover, change fork assy, PTO, bearing, oil seal, mend bag… |

Chassis areas:

| S/N | Products Range |

| one | entrance axle, steering knuckle, restore bag, tie rod finish, drag url, steering tie rod…. |

| two | straight joint, shock absorber, wheel blot, leaf spring assy, wheel hub, gimbal yoke… |

| three | centrale bearing, cross universal joint, transmission shaft, final push, differential system assy… |

| 4 | bearing, brake drum, wheel rim, brake sneakers,brakd pads, hand brake drum, fix bag, clutch pump,.. |

| 5 | brake pump,oil pipe, vacuum booster, buffering rubber, oil seal, electrical power steering box, oil sensor.. |

Packaging & Delivery

If you are intrigued in our merchandise, welcome to get in touch with us.

|

US $2-20 / Piece | |

1 Piece (Min. Order) |

###

| After-sales Service: | One Year |

|---|---|

| Warranty: | One Year |

| Type: | Chassis |

| Certification: | ISO9001 |

| Driving System Parts: | Wheel |

| Electrical System Parts: | Starting System |

###

| S/N | Products Range |

| 1 | Cab Body ASSY, Locking Mechanism, Limiting Device |

| 2 | Cab floor, Bumpers, Fender & Rear Fender, Air spring… |

| 3 | Cab Door, Fog Light, Sun Visor, Hydraulic Lock Assembly… |

| 4 | Steering Column, Front & Rear Glass, Wind-shield Wiper & washer… |

| 5 | Window, Roof Panel, Air Heater system… |

| 6 | Air Conditioner System, Safety Belt, Take Power Off… |

###

| S/N | Products Range |

| 1 | Battery, Auto Horn, Regulator, Flasher, Relay… |

| 2 | Electric Equirments, Sensor, Water Level Buzzer… |

| 3 | Switch, Anti-theft Device, Signal Device, Motor meter… |

###

| S/N | Products Range |

| 1 | Cylinder Head, Cylinder Liner, Crankshaft, Rod… |

| 2 | Piston, Piston Ring, Piston Pin, Piston Cooling Nozzle… |

| 3 | Oil Fitter, Fuel Filter, Water Filter… |

| 4 | Oil Pump, Water Pump, Injection Pump, Transfer Pump, turbo charger… |

| 5. | Main bearing, con.rod bearing, fly wheel, fuel tank, overhaul repair gasket kit… |

###

| S/N | Products Range |

| 1 | gearbox, Gearbox housing, top cover, Primary shaft, Main shaft… |

| 2 | Countershaft, 2 / 3 gear, 2nd speed gear(1/2/3/4/5… |

| 3 | reverse gear ,clutch bearing and seat, synchronize assembly…. |

| 4 | synchronizer slider, synchronizer ring, gearbox shell…. |

| 5 | gearbox cover, shift fork assy, PTO, bearing, oil seal, repair bag… |

###

| S/N | Products Range |

| 1 | front axle, steering knuckle, repair bag, tie rod end, drag link, steering tie rod…. |

| 2 | straight joint, shock absorber, wheel blot, leaf spring assy, wheel hub, gimbal yoke… |

| 3 | centrale bearing, cross universal joint, transmission shaft, final drive, differential device assy… |

| 4 | bearing, brake drum, wheel rim, brake shoes,brakd pads, hand brake drum, repair bag, clutch pump,.. |

| 5 | brake pump,oil pipe, vacuum booster, buffering rubber, oil seal, power steering box, oil sensor.. |

|

US $2-20 / Piece | |

1 Piece (Min. Order) |

###

| After-sales Service: | One Year |

|---|---|

| Warranty: | One Year |

| Type: | Chassis |

| Certification: | ISO9001 |

| Driving System Parts: | Wheel |

| Electrical System Parts: | Starting System |

###

| S/N | Products Range |

| 1 | Cab Body ASSY, Locking Mechanism, Limiting Device |

| 2 | Cab floor, Bumpers, Fender & Rear Fender, Air spring… |

| 3 | Cab Door, Fog Light, Sun Visor, Hydraulic Lock Assembly… |

| 4 | Steering Column, Front & Rear Glass, Wind-shield Wiper & washer… |

| 5 | Window, Roof Panel, Air Heater system… |

| 6 | Air Conditioner System, Safety Belt, Take Power Off… |

###

| S/N | Products Range |

| 1 | Battery, Auto Horn, Regulator, Flasher, Relay… |

| 2 | Electric Equirments, Sensor, Water Level Buzzer… |

| 3 | Switch, Anti-theft Device, Signal Device, Motor meter… |

###

| S/N | Products Range |

| 1 | Cylinder Head, Cylinder Liner, Crankshaft, Rod… |

| 2 | Piston, Piston Ring, Piston Pin, Piston Cooling Nozzle… |

| 3 | Oil Fitter, Fuel Filter, Water Filter… |

| 4 | Oil Pump, Water Pump, Injection Pump, Transfer Pump, turbo charger… |

| 5. | Main bearing, con.rod bearing, fly wheel, fuel tank, overhaul repair gasket kit… |

###

| S/N | Products Range |

| 1 | gearbox, Gearbox housing, top cover, Primary shaft, Main shaft… |

| 2 | Countershaft, 2 / 3 gear, 2nd speed gear(1/2/3/4/5… |

| 3 | reverse gear ,clutch bearing and seat, synchronize assembly…. |

| 4 | synchronizer slider, synchronizer ring, gearbox shell…. |

| 5 | gearbox cover, shift fork assy, PTO, bearing, oil seal, repair bag… |

###

| S/N | Products Range |

| 1 | front axle, steering knuckle, repair bag, tie rod end, drag link, steering tie rod…. |

| 2 | straight joint, shock absorber, wheel blot, leaf spring assy, wheel hub, gimbal yoke… |

| 3 | centrale bearing, cross universal joint, transmission shaft, final drive, differential device assy… |

| 4 | bearing, brake drum, wheel rim, brake shoes,brakd pads, hand brake drum, repair bag, clutch pump,.. |

| 5 | brake pump,oil pipe, vacuum booster, buffering rubber, oil seal, power steering box, oil sensor.. |

The Mechanical Advantage of a Pulley

A pulley is an important tool for many tasks. The advantage that it offers over a hand-held mechanism is its mechanical advantage. In this article, we’ll discuss the types of pulleys and their applications. We’ll also look at the types of compound pulleys. And, of course, there’s a little bit about the mechanical advantage of a pulley. This article will help you decide whether this tool is right for your needs.

Mechanical advantage of a pulley

A pulley has a mechanical advantage over a lever because it is able to produce more force over longer distances. The mechanical advantage of a pulley sounds brilliant and could produce energy. But what exactly is this mechanical advantage? Let’s take a look. First, consider how a pulley works. A rope supports a 100kg mass, which requires 500 newtons of force to lift. If the rope supports a 100kg mass, two sections of rope can support that load. Using a pulley, you can lift the same weight with half the force.

A pulley’s ideal mechanical advantage is the ratio of the force applied to the total length of the rope. The larger the radius, the greater the mechanical advantage. A pulley made up of four rope segments has an ideal mechanical advantage of four. Therefore, a four-segment pulley would multiply the force applied by four. As the numbers on the rope segments are smaller than the total length of the rope, it would be better to use a compound pulley.

The mechanical advantage of a pulley can be calculated by using the T-method. The first step in calculating the mechanical advantage of a pulley is defining the force you need to lift. Then, divide that force by two to calculate the amount of force you need to lift the load. Once you know this amount, you can design a pulley to meet your needs. That way, you can achieve the perfect balance between the two types of pulleys.

Types of pulleys

The main function of the pulley is to change the direction of the force. The mechanical advantages of a single pulley are two. Ideally, two pulleys should have two or more mechanical advantages. The mechanical advantage of compound pulleys can be increased to two or more. The number of pulleys that make up the composite pulley will determine the mechanical advantage. Certain types of pulleys are combined in one housing.

A stepped pulley is a set of pulleys with stepped surfaces. Each face is anchored to the mid-axis in an ordered sequence. This design gives these pulleys their name. They are used to increase and decrease the speed of the driven pulley. Step pulleys are usually used in pairs. They can be straight or stepped, but usually come in pairs.

The three main types of pulleys are pulleys, rope pulleys, and chain pulleys. Pulley Pulley systems use mechanics to lift and lower heavy objects. The Greek historian Plutarch credits the invention of the pulley to Archimedes of ancient Sicily. The Mesopotamians used rope pulleys to lift water around 1500 BC, and Stonehenge is said to have been built using a rope pulley system.

Application of pulley system

The advantages of using a pulley system are numerous. The ability to lift heavy objects is a good example. The pulley system makes it easy for people to lift blocks and other large objects. It can be used in many different applications, from utility elevators to construction cranes. In addition, it is widely used on sailing boats. If you want to learn more about the benefits of a pulley system, keep reading!

You can use the pulley system to water flowers or water plants. Some of them even lowered the pot to make cleaning easier. Pendant lights are another great place to install a pulley system. Climbing and fishing are just some of the activities that utilize the pulley. They are great for fishing and gardening. And since they are so versatile, you can use the pulley system anywhere.

To get the most out of your pulley system, you must choose a product that has all of the above attributes. A high-quality pulley must have a large pulley diameter and be made of sturdy materials. The cables must also be properly supported in the pulleys to ensure a long service life for your investment. A good cable should have minimal cracks and be lubricated. These factors are the most important considerations when choosing a pulley system for your needs.

composite pulley

Composite pulley systems combine two or more movable pulleys. These systems maximize the force to move the weight and can also change direction so they can be used to lift weights. Composite pulley systems can be as simple or as complex as your needs. For example, a pulley pulley system uses multiple pulleys on each axis. This method is often used for hoisting building materials.

A compound pulley system has two or more rope segments, each of which is pulled up on a load. It can increase lift by making objects move faster. These systems are common on large sailboats and construction sites. Composite pulleys are also available for larger boats. Due to their versatility, they are versatile tools for construction sites and large sailboats. If you have their app, you should consider buying one.

The main advantage of composite pulleys is their versatility. You can use them to lift weights or use them to save energy. Composite pulleys are especially useful for lifting heavy objects. For example, you can tie a paper clip to the end of the rope and pull it up. The flag is then lifted into the air with the help of compound pulleys. Composite pulleys are a great invention and they are often used in construction.

security considerations

There are several safety considerations to consider when using pulleys. The first is Secure Workload (SWL). This value is a general guideline for the maximum weight a pulley can safely handle. It varies according to the height and angle of the pulley. Besides SWL, there are some other factors to consider. Consider each one before deciding on the pulley that best suits your needs.

Another safety consideration is the weight of the load. Since the highs of the pulley are higher than the lows, it doubles in weight. The weight of the high point should not exceed 4 kN. The safety factor is calculated by multiplying the strength of the pulley by the weight of the load. Secondary COD has a safety factor of 10:1 and bulletproof primary anchors should be used with pulleys.

If using a chain hoist, you must be trained in the appropriate type of lifting. It is important not to hang on the top hooks of the structure, nor to overload or rig the hooks with multiple slings. You should also avoid corroded or damaged chains, as they can cause the crane to jam or overload. A worn chain can even cause the load to drop.

Components of a pulley system

Proper design of the pulley system can increase the life of the cables and pulleys. Larger diameter cables should be selected as they are more durable than smaller diameter cables. The cables should also be supported in the pulley grooves. The pulley must be designed to be compatible with the cable and its lubrication should be optimal. Proper lubrication of cables and pulleys will ensure maximum durability and longevity.

The first type of pulley is called a fast pulley. These pulleys are used for quick start and stop of the machine. These pulleys are usually mounted in pairs on the countershaft of the machine. One pulley is tightly mounted on the machine shaft, while the other pulley is fitted with a free-spinning mechanism. When the machine is running, the belt is mounted on the tensioner pulley, and when it is stopped, the belt slides on the independent pulley.

Composite pulley sets reduce the overall effort required by reducing the size of the pulley. These are usually attributed to Archimedes. Flat pulleys are often used in flat belt driven transmission systems. These are used in high-speed, low-power applications. Flat pulley idlers are also used on the back of traditional V-belts.

editor by czh 2022-12-20

China Aiwo Idler Pulley for Ford Transit 2.4 Bc1q19A216ba Tensioner Bearing Auto Spare Parts pulley design

Product Description

FAQ

one) How can I place get?

A:You can speak to us by e-mail about your get specifics, or spot purchase on line.

two) How can I pay you?

A:Soon after you verify our PI, we will request you to pay out.T/T (financial institution) and Paypal, Western Union are the most normal ways we are employing.

three) What is actually the purchase process?

A:1st we examine purchase specifics, manufacturing details by e mail or TM.Then we problem you an PI for your affirmation.You will be asked for to do pre-paid out total payment or deposit ahead of we go into generation.Right after we get the deposit, we begin to method the get.We generally need 7-15days if we do not have the things in stock.Just before generation has been completed, we will get in touch with you for cargo information, and the balance payment.After payment has been settled, we start off to get ready the shipment for you.

four)How do you get treatment when your clients obtained defective goods?

A:Substitute.If there are some defective items, we normally credit to our consumer or replace in next cargo.

five)How do you examine all the merchandise in the manufacturing line?

A:We have location inspection and completed merchandise inspection.We verify the products when they go into following phase manufacturing method.

| Type: | Tensioner Bearing |

|---|---|

| Material: | Stainless Steel |

| Certification: | ISO9001, TS16949 |

| Car Make: | Ford |

| Transport Package: | Box and Cartons |

| Specification: | BC1Q19A216BA |

| Type: | Tensioner Bearing |

|---|---|

| Material: | Stainless Steel |

| Certification: | ISO9001, TS16949 |

| Car Make: | Ford |

| Transport Package: | Box and Cartons |

| Specification: | BC1Q19A216BA |

The benefits of using pulleys

A pulley is a mechanical device that converts force into rotation. There are many advantages to using pulleys. Let’s take a look at a few of them. This article will describe the advantages, types, applications, and power sources of pulleys. You can then choose the pulley that best suits your specific needs. If you’re looking for a new tool to help you with a certain task, this article is for you.

Mechanical advantage

The mechanical advantage of a pulley can be defined as the ratio of applied force to the applied force. The mechanical advantage of a pulley can be calculated by considering several factors, including weight and friction. It can be calculated by the force applied per unit length of rope and the number of pulleys used. In a single-circuit system, the force required to lift a heavy object is equal to the user’s body weight.

The mechanical advantage of a pulley can be realized by comparing it to a seesaw. Both uses of rope are suitable for lifting objects. A rope four times heavier than a kilo is four times as effective. Because the forces on both sides of the pulley are equal, a small force is enough to move a large weight a short distance. The same force can be applied to a large mass to lift it several meters.

After introducing the concept of mechanical advantage, learners will practice using the pulley system. In addition to testing the pulley system, they should also calculate its mechanical advantage. Using either the instructor-provided handout or the learner’s workbook, students will determine how easily the pulley system functions. Once they have completed the test, they can discuss their results and how the system can be improved. These courses are best completed as part of a mini-unit or as a standalone main course.

The mechanical advantage of the pulley system is proportional to the number of rope loops. This circuit requires the same force as the dual circuit to lift heavy objects. A single lap requires only a third of the force to lift a double lap, while three laps require almost half the energy required for a single lap. The mechanical advantage of the pulley system becomes constant as the number of cycles increases.

The 3:1 Mechanical Advantage system feels like lifting a 300-pound load with three feet of rope. The three-foot-long rope moves the load one foot high. Understanding the mechanical advantages of pulleys is critical for rescuers when trying to create the perfect pulley system. Ideally, the pulley system will be anchored to a nearby rock, tree, pole or person – if the weight is not too heavy.

Types of pulleys

There are several types of pulleys. V-belt pulleys are the type commonly used in vehicles and electric motors. “V” pulleys require a “V” belt, and some even have multiple V grooves. “V” pulleys are often used in heavy duty applications for power transmission because they reduce the risk of power slippage.

Composite pulleys combine the properties of fixed and movable pulleys. Compound pulleys are able to change the direction of force while requiring relatively low force to move even the heaviest loads. Mechanical advantage is a measure of the effectiveness of a machine or equipment. It can be divided into three categories: force, distance and mechanics. Once you understand how each type works, you can design complex machines.

Fixed pulleys: These pulleys are the most basic type of pulleys. They use ropes and slotted wheels to move with the lifted object. Because they are so simple to set up, lifting heavy objects is a breeze. Although the moving object feels light, it is actually heavier than it actually is. These pulleys are used in construction cranes, utility elevators and many different industries.

Compound Pulley System: A pulley pulley is a combination of two fixed pulleys and one movable pulley. Compound pulley systems are effective for moving heavy objects because they have the largest force multipliers and are flexible enough to change the direction of the force as needed. Composite pulley systems are commonly used in rock climbing, theater curtains and sailing. If you’re looking for a pulley system, you can start by evaluating the types of pulleys and their uses.

Construction Pulleys: These are the most basic types of pulleys and have wheel rails. These pulleys can be lifted to great heights and attached to chains or ropes. They allow workers to access equipment or materials from greater heights. They are usually mounted on wheels with axles and secured with ropes. They are essential tools for construction workers. There are many different types of pulleys out there.

energy source

Belts and pulleys are mechanical devices used to transmit energy and rotational motion. The belt is connected to the rotating part of the energy source, and the pulley is mounted on the other. One pulley transmits power to the other, while the other changes the direction of the force. Many devices use this combination, including automobiles, stationary generators, and winches. It is used in many home applications, from conveyors to treadmills. Pulleys are also used for curtains in theater halls.

Pulley systems are an essential part of modern industry and everyday life. Pulleys are used in elevators, construction sites and fitness equipment. They are also used in belt-driven generators as backup power. Despite their simple and seemingly humble beginnings, they have become a versatile tool. From lifting heavy objects to guiding wind turbines, pulley systems are widely used in our daily lives.

The main reason why pulleys are so popular is the mechanical advantage they offer. They can lift a lot of weight by applying very little force over longer distances. For example, a small motor can pull 10 meters of cable, while a large motor can pull 1 meter. Also, the work done is equal to the force times the distance traveled, so the energy delivered to the large motor is the same.

The power source for the pulley system can be cables, belts or ropes. The drive element in a pulley system is usually a rope or cable. A belt is a loop of flexible material that transmits motion from one pulley to another. The belt is attached to the shaft and a groove is cut in the pulley. The belt then transfers energy from one pulley to the other through the system.

application

A pulley is a mechanical device used to lift heavy objects. They reduce the amount of work required to lift heavy objects and are an excellent choice for many applications. There are several different applications for pulleys, including elevators, grinders, planters, ladder extensions, and mountaineering or rock climbing. Let’s take a look at some of the most popular uses for pulleys in modern society. These include:-

A pulley is a mechanical device that changes force. To use, you wrap the rope around it and pull down to lift the object. While this device is very useful, a major limitation of using pulleys is that you still have to apply the same force to lift the object as you would without the pulleys. This is why people use pulleys to move large objects like furniture and cars.

In addition to lifting heavy objects, pulleys are used in elevators, flagpoles and wells. These systems allow people to move heavy objects without straining their backs. Many other examples of pulleys in the home include garage doors, flagpoles, and elevators. They also help raise and lower flagpoles, which can reach several stories high.

There are two basic types of pulleys: movable and fixed. Fixed pulleys are attached to a ceiling or other object using two ropes. Modern elevators and construction cranes use movable pulleys, as do some weight machines in gyms. Composite pulleys combine movable and fixed pulleys to minimize the force required to move heavy objects.

Another type of fixed pulley is the flagpole. A flagpole can support a country, organization, or anything else that needs to be lifted. A taller flagpole creates a prouder moment for those who support it. The operation of the rope and pulley mechanism is very simple. The user simply attaches the flag to the rope, pulls the pulley, and he or she can watch the flag rise and unfold.

editor by czh 2022-12-07

China manufacturer 24810-23050 2481023050 Engine Parts Timing Belt Kit Tensioner Pulley for Hyundai Elantra Tiburon Tucson KIA Soul 2.0L with high quality

Product Description

Product Description

Timing Belt Tensioner Pulley 24810-23050

| Product Name | Timing Belt Tensioner Pulley |

| Car Model | for Hyundai Elantra Tiburon Tucson Kia Soul 2.0L |

| Brand Name | AL LAMP |

| MOQ | 20 pcs |

| Warrenty | 12 Month |

| Delivery Time | About 3-10 Working Days |

Our advantages:

1. Japanese technology, Chinese ex-factory price

2. Over 20000+ OEM, provide everything you need.

3. Ex-factory price, let you have enough profit

4. There is a 4000+ square warehouse, Large amount in stock, fast delivery

5. Professional auto parts supplier. More than 15 years of experience, worthy of your trust.

Click here to get more about us!

Recomend Product

Customers Feedback

Product Line

We have many kinds of packaging,of course we can accept your own design,

we can customize the packaging for you

Welcome to customize your packaging>>

Company Profile

HangZhou Xin Sande Auto Parts Co., Ltd. was established in HangZhou in 2008. It mainly provides After-market products in ignition system, electronic system, engine system, suspension systems, cooling system for Japanese, American, German, French and Chinese cars, committed to providing customers with high-quality one-stop shopping services.

Over the years, Xin Sande relays on professional team, excellent product quality, and enthusiastic service, has won praises from customers all over the world. Xin Sande has exported more than 100,000 kinds of products to over 120 countries and regions, including Europe, United States, South America, Southeast Asia, Africa, Middle East, etc. Every product is delivered to consumers after going though regular test and inspection.

Xin Sande attaches great importance to training professional skills of staff and insists in visiting different countries every year to provide better service to customers. such as Russia, Uzbekistan, Vietnam, Malaysia, Thailand and other countries .“quality and service takes first priority” as Xin Sande’s mission, Every staff keeps the mission in mind and put it into action.

Xin Sande supports sample products, low minimum order quantity products and Customize products, insists on high-quality products, which wins many regular customers.

Xin Sande is committed to be the primary choice in auto parts industry with the commission of “quality and service takes first priority”. We are dedicated to working together with customers for CZPT cooperation.

Certifications

FAQ

Q: What’s your MOQ?

A: MOQ usually is 20 pieces. (depend on which products you need)

Q: What’s your Payment terms?

A: 30% deposit, 70% balance payment before shipment.

Q: What payment method you accept?

A: Bank Tranfer, T/T, Credit Card, PayPal. Western Union.

Q: How do you control your quality?

A: All products were produced in high standards, and has passed component tests, unfinished tests and 100% products testing before delivery.

Q: How do you ship goods?

A: if you have shipping agent in China, we can send goods to your agent warehouse. If don’t have agent, we will long cooperated shipping company, you can choose by DHL, Fedex, or UPS. or shipping by sea, we will give you several solutions to choose.

Q: Can we customized the length, size or with different materials?

A: Yes, we will try our best to meet most of your needs.

Q: Can you produce the same product as mine if I provide you a sample?

A: Yes, we are capable of producing the electric parts for the most products.

Q: Can you provide me free sample first?

A: It depends on the sample’s cost, normally we can, but client need to pay the shipping cost.

Replacing a Failing Drive Belt Tensioner

A failing drive belt tensioner can be extremely costly. Here’s what to look for and what to do if you suspect yours is bad. In addition, you’ll learn how to identify Idler pulleys and repair it yourself. If the tensioner is failing, you should replace the belt, as well as the Idler pulleys and shaft bearings. But what if the tensioner isn’t faulty?

Symptoms of a bad or failing drive belt tensioner

If your car’s drive belt is not moving smoothly, the pulley may be at fault. Ideally, the tensioner pulley should move away from the engine when the car starts. However, if it stays put or starts to move toward the engine, it’s time to replace the tensioner. The belt may also start to exhibit different wear patterns, such as the uneven wear of the sprockets, bearings, and springs.

If the serpentine belt begins to look loose and the engine loses its luster, the problem is most likely the bad drive belt tensioner. This issue will result in engine vibration. A faulty drive belt tensioner may also lead to a faulty spark plug, which prevents fuel from burning in the combustion chamber. This issue will likely require an engine diagnostic tool, such as an OBD2 scanner, to determine the cause of the check engine light.

Another sign that your drive belt tensioner is failing is a chirping noise. This noise can occur intermittently or constantly, and it may signal a problem with the pulley. In some cases, a faulty pulley may even cause your engine to misfire. Additionally, you may notice that the engine won’t start, even if you engage the starter motor.

In addition to the noise that may come from a failing tensioner, the bad belt tensioner may cause your serpentine to fail. In addition to the noise, this can also lead to overheating of the engine, which can result in costly damages. In addition to causing engine damage, a bad belt tensioner won’t reserve the minimum tension it needs to do its job and may even exceed it, causing the belt to wear out much faster.

If you notice any of these symptoms, it may be time to replace the drive belt tensioner. You can find a replacement OEM part online at a discounted price, as they’re available in wholesale quantities. A Mazda engine typically has no other parts blocking the serpentine belt path, so you can easily find the part you need. After replacing the drive belt tensioner, you’ll need to replace the serpentine belt as well.

Cost to replace a drive belt tensioner

Depending on the location and type of vehicle, replacing a drive belt tensioner can cost between $235 and $267. Some repairs may require other parts, such as a serpentine belt or tensioner housing. RepairPal’s Fair Price Estimator can help you get an accurate estimate for your particular vehicle. You can also contact HomeX, a virtual repair shop that can fix simple issues like loose drive belt tension.

It’s a relatively simple DIY job for most cars. An experienced mechanic will be able to replace the belt in a half hour or less, depending on the type of car and how many parts are affected. Depending on the complexity of the repair, the labor to replace the drive belt tensioner could cost anywhere from $50 to $170. The labor to replace the drive belt tensioner is typically included in the quoted price, but some auto shops may charge more to replace other car parts as well.

Replacing the drive belt tensioner is a relatively easy task. While the process might take an hour or more, it will be worthwhile in the long run. Regular inspections can prevent costly repairs by identifying problems before they cause major damage. A car’s belt is essential to the operation of the engine and can’t be operated without it. Changing it can save you money, as it will save you from spending extra on unnecessary parts.

Thankfully, there are plenty of tools available to help you replace your drive belt. While it may not be the easiest repair, it will still cost less than a mechanic’s service call. It is better to replace the belt early than to wait for the vehicle to break down, as this will prevent more expensive parts from breaking. You may also consider investing in a premium belt, which will give you twice as much mileage as a cheaper one.

While a drive belt tensioner is generally considered a wear-and-tear item, it is a part that should last the entire life of the vehicle. You can expect to replace the drive belt tensioner no earlier than 125,000 miles, but it is better to do it early if your car isn’t that old. And it doesn’t hurt to check the owner’s manual for directions on how to replace the drive belt tensioner.

Idler pulleys

Idler pulleys may seem like a minor part of your car, but their important job is to keep various components in good working order. Fortunately, they are inexpensive and don’t need much maintenance. If 1 pulley fails, it is best to replace all of them. However, it is not always easy to check idler pulleys yourself. It’s recommended that you visit a professional auto repair shop that is ASE-certified to inspect and replace the idler pulley.

Depending on the size and type of idler pulleys you need, you’ll have to purchase 2 or 3 pieces. You’ll need to purchase a pair of pliers for this part, as well as a tensioner pulley wrench. The cost of a replacement idler pulley will vary by make and model, but you can expect to pay between $40 and $200. These prices don’t include taxes or fees. Because they are so essential to drive belts, it’s worth investing in 1 or two.

Idler pulleys are a vital part of a car’s engine. They’re found underneath the hood and are usually 2 to 4 inches in diameter. They run over a roller that’s used to tension the belt. The belt is wrapped around a series of engine parts, and the idler pulleys are a complement to each other. You may not need an idler pulley on your car, but your mechanic will install it for you if you don’t.

The idler pulleys for a belt tensioner are crucial parts of your car’s engine. If they are worn down, the belt is likely to move loosely over them. Corrosion may also make the idler pulley move less freely. If the idler pulley is slipping, the belt may jump over the pulley, and the squealing noises will indicate a serious problem.

The idler pulley is a pivotal part of the engine’s power train. It redirects the path of the serpentine and timing belts, so that they can make optimal contact. The larger the contact patch, the more power the belt will transfer. The idler pulley can also improve the vehicle’s performance. It is a vital part of the engine, so make sure you check it frequently and install it correctly.

Repairing a drive belt tensioner

Replacing a drive belt tensioner is relatively simple. While your belt may need to be replaced, other parts of your engine may also need to be fixed. Typically, the tensioner will be replaced along with the pulley, as both parts are prone to malfunction. Replacing the drive belt tensioner is a fairly straightforward job, and it should only take about an hour or two. By following these simple steps, you can save yourself a lot of money and time.

You can detect the problem by observing the belt glazing. Typically, it occurs when the tensioner does not have enough spring tension. Another sign of a failed component bearing is excessive arm oscillation. Excessive chattering and oscillation indicate that the damper has worn out. If you notice excessive oscillation, you should replace the tensioner pulley. Otherwise, you might be dealing with a defective bearing.

A damaged or out-of-adjusted drive belt will make a squealing noise. This is due to the belt slipping on the pulleys. It is most noticeable when the car is first started in the morning. A damaged drive belt will also be hard to manipulate. The new belt should be the same length and width as the old one. You can check the tensioner by pulling the belt and compressing it.

A worn-out drive belt tensioner will result in unusual noise, excessive wear, and a loose belt. This is especially affecting if the car is equipped with a serpentine belt. The drive belt tensioner has a roller bearing that can wear out, which will cause a squealing noise or even cause the belt to roll off entirely. Because of its important role in engine operation, it is vital to check the condition of the drive belt tensioner on a regular basis.

While replacing a drive belt tensioner may seem like a simple DIY project, you should consult a mechanic before undertaking the work. The parts and labor costs of a drive belt tensioner repair can range from $140 to $400, and you should allow an hour for this repair. If you are not comfortable performing the repair yourself, you can always hire a mechanic to do it for you. In most cases, a drive belt tensioner replacement will cost approximately $70 to $80 and take about an hour.

China Standard Timing Belt Tensioner Pulley 25286-2b010 for Hyundai KIA with high quality

Product Description

| Subject | Timing Belt Tensioner Pulley 25286-2B571 for Hyundai Kia |

| Item Name | tensioner pulley |

| Part number | 25286-2B571 |

| Car Model | for hyundai kia |

| Material | alloy |

| MOQ | 20pcs |

| Warranty | 6 months |

| Price term | EXW HangZhou |

| Package | white box |

| Payment | T/T, Western Union, Paypal |

| Delivery time | small order about 3-7 days,big order about 15-30 days |

| Shipping Way | Express like DHL/Airline/Sea/Land transportation |

| Sea Port | Hongkong |

What to Look for in a Belt Tensioner

If you notice the power steering, air conditioning, or power steering stops working, chances are that your belt tensioner has been compromised. A compromised belt tensioner can be completely destroyed overnight, or it can last for a long time before it breaks. Either way, you should never drive with a faulty belt tensioner. It’s far better to have it replaced before the engine shuts down completely. In addition, replacing a belt tensioner will prevent other complications, such as power steering or air conditioning, from occurring.

Misaligned idler pulley

If the tensioner arm is not rotating freely or has an abnormal chirping noise, it could be the result of a misaligned idler pulley. If this is the case, replace the idler. If the idler does not move, you may need to adjust the accessory mount points or use a laser alignment tool. The tensioner arm is only 1 part of the tensioner.

A misaligned idler pulley on a belt tensioner is usually the cause of a squeaking noise. If this noise continues even after a replacement of the belt, it’s time to replace the whole belt. A misaligned idler pulley can also be the cause of premature belt wear. If the idler pulley is out of alignment, it could also cause the belt to wear too fast and lead to the premature failure of the timing belt.

The tensioner pulley is made of nylon, steel, or plastic. It may be flat or grooved. Before replacing it, check for any cracks, dents, or debris on the pulley’s surface. Plastic pulleys may have broken sidewalls. If the idler pulley is worn out, you might also notice squealing noises when the vehicle is in motion.

The misalignment of a belt is most pronounced when the span between the 2 pulleys is short. When the span is long, however, diagnosing the problem becomes more complicated. Small degrees of offset may not be visible to the naked eye, but a laser alignment tool can help identify these subtle variations. In order to identify a misaligned idler pulley on a belt tensioner, you must first determine its cause.

When the tensioner’s idler pulleys are out of line, a belt tensioner will not be able to properly adjust the torque that the belt is under. This may result in squealing noises. If this is the case, it is time to call a mechanic. He or she will be able to determine the cause and correct it. If you suspect the problem, your next step is to replace the idler pulley on the belt tensioner.

If the ribbed belt is not properly aligned, you may have a misaligned idler pulley. To fix the misalignment, locate the belt adjustment bolt underneath the hood. You should be careful not to damage the alternator or battery terminal while doing this task. If you do accidentally connect the battery positive to the earth, you might be able to damage the ribbed belt and ruin your vehicle’s timing.

Besides a misaligned idler pulley on the belt tensioner, another problem may be the alternator’s serpentine belt. If your car’s alternator belt is not aligned properly, you could have misaligned the alternator’s pulley or a worn-out bearing. Regardless of the cause of your problem, you should have the belt inspected.

Bad idler pulley

Having a Bad Idler Pulley on a Belt Tensioner? If this sounds familiar, then it’s probably time to change it. Idler pulleys slowly take hits while the engine is running, causing the belt to wrap and bend. Eventually, the belt will slip, and a new idler pulley should be installed to ensure optimal tension. But before you spend a dime on a new one, let’s talk about what to look for.

Symptoms of a Bad Idler Pulley: If the noise persists, there is a problem with the idler pulley or its bearing. These parts wear out over time and may eventually cause a cracked idler pulley or serpentine belt. Not only will the idler pulley create an irritating noise, but it will also damage the belt itself, leading to overheating, stalled engine, and even damage the head gaskets. Thankfully, a Bad Idler Pulley on a Belt Tensioner is easily replaced and will only cost about $40.

Although the Idler Pulley is not the most popular component on a car, it’s a critical part that ensures that the engine runs smoothly. It’s easy to overlook this part, but its failure can make it impossible for your vehicle to operate at its optimal level. Moreover, a Bad Idler Pulley on a Belt Tensioner will cause your engine to malfunction, so it’s essential that you check it at regular intervals.

If you notice a squealing noise while driving, the Idler Pulley is likely the culprit. Because of friction between the engine belt and idler pulley, the engine belt rubs against the pulley, causing it to squeak and make a clicking noise. This squealing noise will continue until the problem is repaired or replaced. It’s time to start addressing the problem before it becomes too late.

If you notice the tensioner pulley moving away from the engine, it’s most likely that the pulley is malfunctioning. A belt that is loose or slack may make it difficult to start the car, or your engine may even overheat. If this occurs, it’s crucial to replace the Idler Pulley as soon as possible, because a Bad Idler Pulley on a Belt Tensioner can seriously damage your vehicle.

The Idler Pulley facilitates the motion of the engine belt. It serves as a smooth rotating point that allows the belt to loop without a barrier. Over time, this part of the system will begin to show signs of wear and tear, and replacement is vital to protect your engine, serpentine belt, and other accessories. An early warning sign of a problem is a squealing sound coming from the engine area.

Broken tensioner arm

The belt tensioner is a piece of machinery that is used to keep the belt tight. If this part breaks, you can easily repair it yourself using a long-handled ratchet, serpentine belt tool, or a socket. To repair the tensioner, simply remove the drive belt from the pulley and rotate it to release tension. Check for roughness, resistance, or binding of the drive belt.

Noises caused by the tensioner are a sign of a damaged component or excessive oscillation. These noises are usually caused by worn internal components or the tensioner’s pivot bushing. In some cases, the vibration damping system or a worn-out alternator pulley could also be to blame. If this is the case, replace the pulley and tensioner together. To check the condition of your belt tensioner, follow these steps.

In addition to worn-out springs, a loose or broken pivot arm could be causing your belt to misalign. A worn-out tensioner pulley bushing will also cause vibrations, noise, and seizing. Lastly, a broken tensioner spring could be preventing the belt from maintaining proper tension. Broken springs are also prone to loss of tension due to heat. Damaged tensioner housing can also affect belt tension.

Once the belt is installed, you need to check the condition of the pulley and the tensioner arm. Make sure that the pulley is moving and that the arm is moving smoothly with the cranking and releasing. If the arm is wobbling, the tensioner is failing. If the pulley wobbles or excessive chattering occurs, the tensioner is failing. It can also be seized or jammed.

If the tensioner arm has broken, replace it. Replacing the tensioner can be a tedious task. Be sure to use a suitable tool to tighten the pulley and tensioner. If you are not sure of how to replace the pulley, try using a serp belt tool. Another good option is to purchase a 3/8 drive ratchet. If you don’t have this tool, you can use a long 3/8 extension and a deep socket.

The belt tensioner assembly can fall off the engine, causing damage to the timing belt. If you are replacing it, you must replace it with a new one, and tighten all of the mounting bolts before reinstalling it. To avoid further damage to the engine, ensure you replace the belt with a new tensioner and a new belt. The tensioner is bolted to the engine’s timing cover, so make sure you carefully tighten the bolts when replacing it.

China manufacturer Belt Tensioner Vkm 31041 Idler Pulley for Autoparts and Motor Parts near me factory

Product Description

Product Description

Product Name: Belt Tensioner VKM 31041 Idler Pulley for auto parts and motor parts

Parameter:

Outer Diameter: 64 mm

Inner Diameter: 17mm

Height: 26.5 mm

Weight: 0.43kg

The VKM31041 belt tensioner is suitable for Audi, Mercedes Benz, Volkswagen

Carfitment and part number

OEM No. of the Belt Tensioner VKM 31041

CHRYSLER : AA

CHRYSLER : 5 0571 16AA

CHRYSLER : 68571888AA

MERCEDES-BENZ : 05712

Our Products:

Our company supplies a wide range of auto parts, such as belt tensioner, wheel bearing & hub assembly, clutch release bearings, motor bearings, rod bearing, crankshaft bearing, etc. If there are any needs of auto spare parts, please don’t hesitate to send us an inquiry, we will offer the price for your reference.

A wide range of applications of bearings:

• agriculture and forestry equipment

• automotive and industrial gearboxes

• automotive and truck electric components, such as alternators

• electric motors

• fluid machinery

• material handling

• power tools and household appliances

• textile machinery

• two Wheeler

Company Profile

Our Advantages

1. ISO/TS16949 Standard

2. Small order accepted

3. In Stock auto bearing

4. OEM bearing service

5. Professional Technical Support

6. Timely pre-sale service

7. Competitive price

8. Full range of products on auto bearings

9. Punctual Delivery

11. Excellent after-sale service

12. One stop service

Packaging & Shipping

| Packaging Details | 1 piece in a single box 50 boxes in a carton 20 cartons in a pallet |

| Nearest Port | ZheJiang or HangZhou |

| Lead Time | For stock parts: 1-5 days. If no stock parts: <200 pcs: 15-30 days ≥200 pcs: to be negotiated. |

FAQ

If you have any other questions, please feel free to contact us as follows:

Q1. What are your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have a legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What are your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance.

Q3. What are your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have a 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Contact Us

Why You Should Get a New Timing Belt

A timing belt is a rubber belt with teeth that transfer rotary motion from the central motor to the drive pulley. It prevents the piston from striking the valves at a critical level. Unfortunately, these belts cost a lot to replace. Here are some reasons why you should consider getting a new one. If you’re not sure whether a new timing belt is necessary, read on. You can also save money by avoiding unnecessary repairs and replacements by choosing an aftermarket timing belt.

Timing belts are rubber belts with hard teeth

While it’s true that timing belts are commonly known as “drive belts,” there are several different types of belts that are used in engines. Despite their commonity, timing belts are made of different materials. The material used to make them is important because it can either negatively impact performance or negatively affect its life span. Whether it’s a car, truck, or motorcycle, timing belts are an essential part of your engine.