Product Description

IHF 3D Printed Type MXL XL HTD3M HTD5M 2GT P5M AT10 Timing Belt Idler PulleysTiming Belt Idler Pulleys

Product Description

Specification:

| Describtion | Standard timing pulley(Customized) |

| Material | AL6061/Steel/ SUS304 |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching,Gear Shaving, Gear Grinding and Gear Lapping |

| Heat Treatm | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding. |

| Finish | No cuting oil,metal chip & scratch are allowed on surface |

| Teeth Profile | MXL,XL,L,T5,T10,T20,AT5,AT10,AT20,2M,3M,5M,8M,2GT,3GT,5GT etc. |

| Standard | DIN, ISO/GB, AGMA, JIS |

| Samples | Offer for free |

Advantages:

- High temperature resistance.Self lubrication.Wear resistance.Flame retardant properties.

Basic Information:

| Specification | Standard or Custom made |

| Material | Stainless steel,,brass, carbon steel, aluminum, and so on. |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, Copper-plating, the wreath oxygen resin spraying, black oxide coating, painting, powdering, color zinc-plated,blue black zinc-plated, silver plating,anodizing etc. |

| Main Products | Precision spur gear, Timing pulley, Bevel pulley, Worm& worm gear, Timing Belt.. |

| Producing Equipment | CNC machine , automatic lathe machine,stamping machine,CNC milling machine,rolling machine, lasering, tag grinding machine etc. |

| Management System | ISO9001 – 2008 |

| Testing Equipment | Projecting apparatus, Salt Spray Test, Durometer, and Coating thickness tester , 2D projector |

| Lead time | 10-15 working days as usual, 30days in busy season, it will based on the detailed order quantity. |

| Delivery of Samples | By DHL, Fedex, UPS, TNT, EMS |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

Machining Process

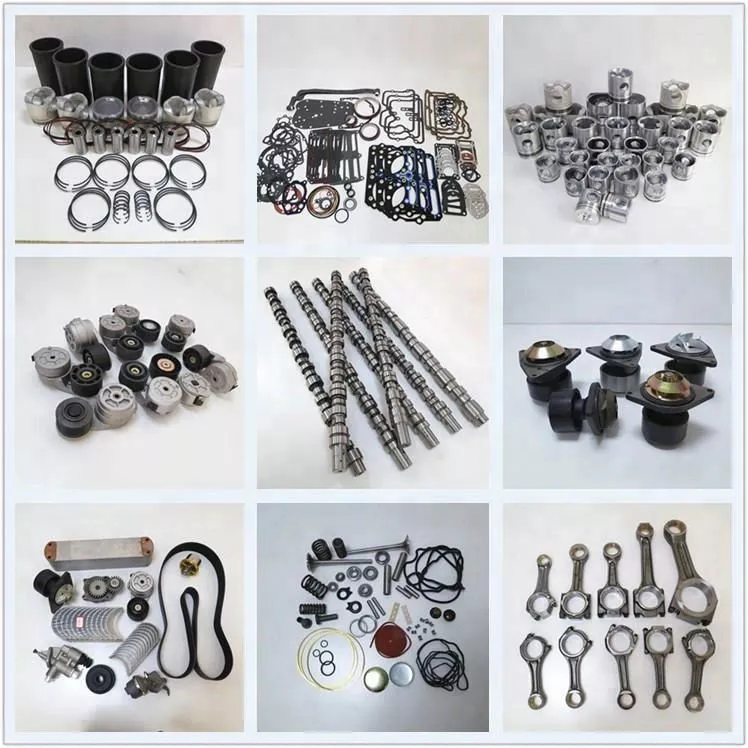

Related Products

Company Profile

HangZhou CZPT Machinery Co.,LTD established in 2009, is a professional manufacture engaged in development, production, sales and service of timing pulley, precise spur gears, helical gears, bevel gear, worm& worm gear and so on. We located in HangZhou with convenient transposition excite. CZPT Machinery dedicated to strict quality control and thoughtful customer service. Our experienced staffs are always available to discuss your requirements, and fulfill your satisfaction.

Packaging & Shipping

Packaging Details: standard exporting package

Delivery Detail: 30days after received the prepayment

FAQ

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order | * You send us drawing or sample |

| * We carry through project assessment | |

| * We give you our design for your confirmation | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you! |

Tips For Replacing a Belt Tensioner

When replacing a serpentine belt or automatic tensioner, you will need a special tool. This tool has a long, flat extension handle that allows you to place a socket onto the bolt and flats on the tensioner arm. The following are some tips to follow when replacing the belt or tensioner on your vehicle. To replace your belt or tensioner, you should start by checking the tensioner’s lubrication.

Serpentine belt

If you notice that the power steering or air conditioning are not working, you should check the serpentine belt tensioner. A malfunctioning serpentine belt tensioner can lead to a host of other issues. The belt may stretch, which can be caused by several factors. Over time, serpentine belt tensioners can also get worn down. Additionally, they can have a variety of other problems, including rust or dirt in the housing.

You can replace your serpentine belt by following the instructions found on your vehicle’s manual. Some tensioners attach to the engine via a single bolt. To remove and replace the belt, remove the old unit and the retaining bolt. Locate the locking pin in the engine and place the new tensioner over it. Use a torque wrench or hand tool to tighten the bolts. When installing the new tensioner, be sure to line up the mounting bolt holes with the mounting bolts. Once the tensioner is installed, test the tension by ensuring that the gauge is above the ribs. If it slides down, it is time to replace the tensioner.

Before you begin the process of replacing your serpentine belt, be sure to park your vehicle in a level area. Turn off the engine and chock both rear wheels before starting the process. Using a diagram from your vehicle’s repair manual can make the process easier, especially if you are a beginner. You can draw it in your hand, or refer to a repair manual to find out the exact location of the tensioner pulley.

If you notice that the belt is slipping or squealing while driving, it may be time to replace the serpentine belt tensioner. A worn-out belt can cause the belt to slip and can cause power steering, air conditioning, and alternator malfunctions. You should also check the belt tensioner regularly. The motor may stall or make a loud noise. These are all signs of worn-out serpentine belt.

A serpentine belt uses less space in the engine than a V-belt. It also provides more tension for the serpentine belt, which prevents it from running hot and squealing. Serpentine belts are manufactured to last for several hundred thousand miles. They are a must-have item for your car! So be sure to keep it maintained and properly adjusted! Then, you can be sure to have your car running smoothly and safely.

If you notice any of these symptoms, you should replace your serpentine belt tensioner. A serpentine belt tensioner is a simple self-10sioning device that is mounted on the front of the engine. These devices are usually easy to replace and are not complicated to install. You can find 1 at any parts store or online. When the time comes to replace your serpentine belt, don’t hesitate to get the parts you need from a local auto part store.

Idler pulley

The idler pulley and the belt tensioner are essential components of your car’s drivetrain. If any 1 of them fails, all of them must be replaced. This is because they were manufactured at the same time and most likely have the same number of miles on them. As a result, they can all fail within a few thousand miles of each other. Here are some of the symptoms that you should look for when inspecting your idler pulley or belt tensioner.

Idler pulleys are a common part of most cars. They play a vital role in the operation of the belt system by directing the belt’s path and providing additional contact with the pulley. The idler pulley is also responsible for turning the cooling fan in an air-cooled Corvair engine. Because of these functions, idler pulleys are often replaced with idlers that differ in size.

Idler pulleys are small, 2 to 4 inches in diameter and mounted on the front of the engine block. Their purpose is to create a constant amount of tension on the drive belt. When the idler pulley is worn out, the accessory drive belt may experience excessive vibration and squealing noises. You may wish to replace it as soon as possible. You can do so at AutoZone.

A worn or damaged idler pulley will require a replacement. The belt itself will not fall off the car unless the idler pulley is damaged. A squealing sound can be a sign of a broken spring. Alternatively, a mechanic can recommend a replacement based on the condition of the idler pulley. In most cases, idler pulleys are more durable than the belts and are therefore recommended for replacement.

You can also notice that the idler pulley is slipping or causing excessive noise. Its constant rotation wears the idler pulley and reduces the tension of the belt. This causes the belt to slip and may even tear off the engine. Ultimately, this could result in stalling. And if you notice the engine belt squealing or making excessive noises, you should consider replacing it.

An idler pulley for a belt tensioner are often confused. Though both of them are used in the same application, they differ in many ways. The tensioner is the 1 that receives pressure from the belts and moves them. The idler pulley is not attached to an adjustable bolt, and it can cause unusual noises. It might even make squealing or odd noises.

Spring tensioner

A spring belt tensioner is a solution to a loose belt. It features a strong torsion spring that reduces slack. These devices are designed to fit up to 6mm wide belts. They are highly reliable and durable. They are also suitable for applications where the engine speed is often fluctuating. Here’s how you can choose the best 1 for your vehicle. The spring in the tensioner should be in the proper position to keep the belt taut and free of slippage.

The RunRight tensioner is a durable, high-quality product that uses aluminum alloy. Its elastomeric inserts rely on highly elastic natural rubber for good shape memory and durability. Spring tensioners are easy to install and maintain. They are designed for both axial and helical drives. They feature detailed technical drawings and 3-D models to help you determine the best 1 for your application. To choose a spring tensioner, visit our website.

A worn bushing in the tensioner pulley or a loose pivot arm can result in excessive noise, vibration, and premature belt failure. In addition, worn springs cannot maintain proper tension. Over time, they lose tension. The pulley arm itself can also become damaged, preventing it from rotating properly. If these problems occur, you’ll need to replace the spring tensioner. If you don’t see any signs of wear, check your mounting bracket and tensioner.

A worn pivot bushing can cause the tensioner arm to misalign, leading to excessive back and forth sway. It may also cause the tensioner to jam, which means the belt is too long or too short. If you notice excessive wobble, you should replace the spring tensioner. A faulty tensioner may also be causing excessive oscillation in the pulley. To determine if the spring tensioner is too weak or jammed, check the belt’s length by using a breaker bar or socket with a long handle ratchet.

When it’s time to replace your serpentine belt, don’t forget to replace the belt tensioner. The tensioner protects other components from premature failure. It is a relatively inexpensive repair. It should be replaced as part of a larger multi-ribbed belt. It also provides protection for other components of the drive system. In addition to its protection and performance, the tensioner is inexpensive and relatively easy to replace.

It’s vital to check the tensioner and idler pulleys to make sure the system is aligned properly. If they don’t align, the belt will slip and cause premature wear. Alternatively, the tensioner may have too much tension, overloading the shaft bearings and causing premature failure in other parts. You should also check the idler pulleys for noise as well, since these are engine-driven accessories.