Product Description

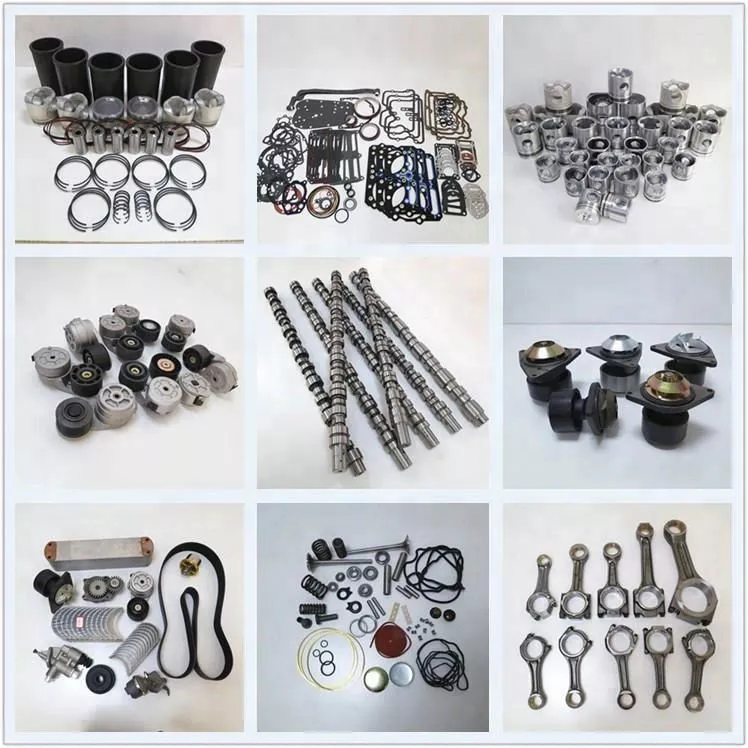

OUR MAIN Products

Product Description

Belt Tensioner

| Item Name | Belt Tensioner |

| OE NO. | 20747516 |

| Suitable For | For Truck |

| Delivery Time | Normally ship within 1-30 Days after payment or as customers’ requirement, depend on stock |

| Exclusive Advantages | 1. Factory direct with lower price. 2. Most of the items in stocks,we can ship the goods in a short time. 3. Sincere service and independently professional after sale service. Any problem after you received the goods, please contact us in time,the best solution will be offered. |

Our advantages:

1. Japanese technology, Chinese ex-factory price

2. Over 20000+ OEM, provide everything you need.

3. Ex-factory price, let you have enough profit

4. There is a 4000+ square warehouse, Large amount in stock, fast delivery

5. Professional auto parts supplier. More than 15 years of experience, worthy of your trust.

Click to know more about us!!

Our Advantages

Company Profile

Certifications

Our customers

Packaging & Shipping

FAQ

Q1. What is your terms of packing?

We have many kinds of package,of course your own design will be accepted,we could custom the package for you

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF,

Q4. How about your delivery time?

A: Generally,we use EXW, it will take 3 to 6 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery? A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship? A:1. We keep good quality and competitive price to ensure our customers benefit ; 2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 12 Month |

|---|---|

| Warranty: | 12 Month |

| Type: | Truck |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there specific considerations for choosing drive belt tensioners in vehicles with varying loads or environmental conditions?

Yes, there are specific considerations to take into account when choosing drive belt tensioners for vehicles that operate under varying loads or in different environmental conditions. The selection of appropriate tensioners is crucial to ensure optimal performance, reliability, and longevity in such situations. Here’s a detailed explanation of the specific considerations when choosing drive belt tensioners for vehicles with varying loads or environmental conditions:

- Load Capacity:

- Temperature and Moisture Resistance:

- Dust and Contaminant Protection:

- Vibration and Shock Resistance:

- Adjustability and Maintenance:

Vehicles that operate under varying loads, such as trucks or vehicles used for towing, require drive belt tensioners with higher load capacities. The tensioners must be able to withstand the additional forces and loads imposed by heavy loads or towing applications. When selecting tensioners, it is important to consider their load rating, which indicates the maximum load they can handle without compromising performance or longevity. Choosing tensioners with suitable load capacities ensures that they can maintain proper belt tension and functionality under varying load conditions.

Environmental conditions, including temperature and moisture levels, can significantly impact the performance and longevity of drive belt tensioners. Vehicles operating in extreme temperatures, such as hot desert environments or cold winter climates, require tensioners that can withstand these conditions. Tensioners with materials and coatings specifically designed for temperature resistance, such as high-temperature seals or heat-resistant coatings, are recommended. Similarly, in high-moisture environments, tensioners with corrosion-resistant coatings or materials should be chosen to prevent rust and degradation caused by moisture exposure.

In environments with high levels of dust, dirt, or other contaminants, it is important to choose drive belt tensioners that offer effective protection against these elements. Dust and contaminants can accumulate on the tensioner pulley or in the tensioner mechanism, leading to increased friction, wear, and potential belt slippage. Tensioners with features such as sealed bearings, dust covers, or protective coatings can help prevent the ingress of contaminants and ensure reliable performance even in dusty or dirty conditions.

Some vehicles, such as off-road vehicles or heavy machinery, are subjected to high levels of vibration and shock during operation. These dynamic forces can impact the performance and longevity of drive belt tensioners. It is important to choose tensioners that are specifically designed to withstand vibrations and shocks. Tensioners with robust construction, reinforced components, and vibration-damping features can help mitigate the effects of vibrations and shocks, ensuring reliable belt tensioning and minimizing the risk of premature failure.

In vehicles with varying loads or operating conditions, having adjustable tensioners or tensioners with easy maintenance features can be beneficial. Adjustable tensioners allow for fine-tuning of belt tension based on load requirements or changes in environmental conditions. Tensioners with accessible adjustment mechanisms or quick-release features simplify maintenance and belt replacement, reducing downtime and ensuring optimal tensioning performance.

Considering these specific factors when choosing drive belt tensioners for vehicles with varying loads or environmental conditions is crucial to ensure proper performance, reliability, and longevity. It is recommended to consult the vehicle manufacturer’s specifications, technical documentation, or seek expert advice to select tensioners that are suitable for the specific operating conditions and requirements of the vehicle.

Can you provide examples of symptoms indicating a malfunctioning drive belt tensioner in a vehicle?

A malfunctioning drive belt tensioner in a vehicle can exhibit various symptoms that indicate a potential issue. Recognizing these symptoms is important as it allows for timely inspection and repair to prevent further damage to the drive belt system. Here are some examples of symptoms that may indicate a malfunctioning drive belt tensioner:

- Squealing or Screeching Noises:

- Visible Belt Misalignment:

- Belt Slippage or Glazing:

- Belt Wear or Damage:

- Malfunctioning Engine Systems:

A common symptom of a faulty tensioner is the presence of squealing or screeching noises coming from the engine compartment. These noises can occur when the tensioner fails to maintain proper belt tension, causing the drive belt to slip or lose grip on the pulleys. The squealing or screeching sound is a result of the belt rubbing against the pulleys or other engine components. If the tensioner is not functioning correctly, it may not apply sufficient pressure on the belt, leading to this noise.

If the drive belt tensioner is not properly aligned or functioning correctly, the drive belt may appear misaligned or off-center. This misalignment can be visually noticeable when inspecting the belt in the engine compartment. A misaligned belt can cause uneven wear, increased friction, and reduced power transmission efficiency. It is important to address this issue promptly to prevent further damage and potential belt failure.

A malfunctioning tensioner can lead to belt slippage or glazing. Belt slippage occurs when the tensioner fails to maintain proper tension, causing the belt to slip on the pulleys. This can result in reduced power delivery to the driven components, leading to decreased performance or functionality. Glazing, on the other hand, refers to a shiny appearance on the belt’s surface due to excessive heat and friction. Both belt slippage and glazing are indications of an inadequate tensioner function and should be addressed promptly.

A malfunctioning tensioner can contribute to accelerated wear or damage to the drive belt. Excessive belt wear can occur due to inadequate tension, misalignment, or abnormal belt movement caused by a faulty tensioner. Signs of belt wear include cracks, fraying, or missing chunks of the belt material. If the tensioner is not functioning correctly, it can put additional stress on the belt, leading to premature wear and potential belt failure. Regular inspection of the drive belt for signs of wear and damage is crucial to identify any potential issues with the tensioner.

A malfunctioning drive belt tensioner can also impact the performance of various engine systems. If the tensioner fails to maintain proper belt tension, it can result in inadequate power delivery to components such as the alternator, power steering pump, air conditioning compressor, or water pump. This can lead to issues such as dimming lights, difficulty in steering, reduced cooling efficiency, or a malfunctioning air conditioning system. If multiple engine systems are experiencing problems simultaneously, it could be an indication of a faulty drive belt tensioner.

It is important to note that these symptoms can also be caused by other issues related to the drive belt system. Therefore, a comprehensive inspection by a qualified mechanic is recommended to accurately diagnose the cause of the symptoms and determine if the drive belt tensioner requires repair or replacement.

Can you explain the importance of proper tensioning for drive belts in cars and trucks?

Proper tensioning for drive belts in cars and trucks is of utmost importance for the efficient and reliable operation of the vehicles. Maintaining the correct tension in the drive belts ensures optimal power transfer, prevents slippage, reduces wear and noise, and contributes to the overall performance and longevity of the vehicles. Here’s a detailed explanation of the importance of proper tensioning for drive belts:

- Efficient Power Transfer:

- Prevention of Belt Slippage:

- Reduced Wear and Noise:

- Optimal Performance and Reliability:

- Safety Considerations:

Proper tensioning of drive belts allows for efficient power transfer from the engine to various components such as the alternator, power steering pump, air conditioning compressor, and water pump. When the belts are properly tensioned, they maintain a positive grip on the pulleys, ensuring maximum frictional contact. This efficient power transfer minimizes energy losses and optimizes the performance of the vehicle’s systems, resulting in improved overall efficiency and performance.

Drive belt slippage can occur when the belts are either too loose or too tight. Loose belts can slip on the pulleys, resulting in reduced power transmission and impaired operation of the vehicle’s accessories. On the other hand, excessively tight belts can cause excessive strain on the components and lead to premature wear. Proper tensioning ensures that the belts remain securely engaged with the pulleys, preventing slippage and maintaining effective power transfer.

Correct tensioning helps reduce wear on the drive belts and associated components. When the belts are properly tensioned, they experience minimal movement and vibration, resulting in reduced friction and wear. This extends the lifespan of the belts and reduces the frequency of belt replacements. Additionally, proper tensioning helps dampen belt vibrations, resulting in reduced noise levels. This contributes to a quieter and more comfortable driving experience.

Proper tensioning of drive belts is crucial for achieving optimal performance and reliability in cars and trucks. When the belts are tensioned correctly, the vehicle’s systems and components receive the necessary power to operate efficiently. This includes components such as the alternator, which charges the battery and powers the electrical system, and the power steering pump, which assists in steering. By maintaining the correct tension in the drive belts, the vehicles can operate reliably, ensuring smooth operation, minimizing the risk of component failures, and reducing the likelihood of unexpected breakdowns.

Proper tensioning of drive belts also has safety implications. For example, the water pump is driven by a belt and plays a critical role in cooling the engine. If the belt is not properly tensioned and slips or breaks, it can result in engine overheating, potentially leading to engine damage and safety hazards. Similarly, the power steering system relies on the drive belt to operate properly. Insufficient tension can cause power steering failure, making it more difficult to steer the vehicle, especially at low speeds or during maneuvers. Proper tensioning helps ensure the safe and reliable operation of these critical components.

In summary, proper tensioning for drive belts in cars and trucks is crucial for efficient power transfer, prevention of belt slippage, reduction of wear and noise, optimal performance and reliability, and safety considerations. By maintaining the correct tension in the drive belts, vehicles can operate smoothly, maximize power transfer efficiency, minimize wear on components, and ensure the safe and reliable operation of critical systems. Regular inspection and adjustment of belt tension are essential maintenance practices to ensure the longevity and performance of the vehicles.

editor by CX 2024-03-04

China factory Alternator Belt Tensioner Pulley for VW 377145299 5W0145299 cv axle replacement

Product Description

Product Description

Alternator Belt Tensioner Pulley for VW 377145299 5W0145299

Timing Pulley Idler pulley belt tensioner Details

1. Alternator Belt Tensioner

Outer Diameter: 70mm

Width: 26mm

Drive Type: Mechanic

2. Packing:

A. Neutral packing with kraft paper box or carton

B. As per the customer’s requirement

3. MOQ: 50Pcs

4. Quality Warranty: 12 Month

OEM NUMBER

|

AUDI : AUDI : 5W0 145 299 SEAT : SEAT : 5W0 145 299 |

SKODA : SKODA : 5W0 145 299 VW : VW : 5W0 145 299 |

REFERENCE NUMBER

|

AUTE X : 654276 IN A : 534016510 INTERBRAK E : 5340165 INTERBRAK E : 5340165.2 |

VKBA523 | 482A/472 | VKBA 5038 | 35BWD16 | VKM14103 |

Company Profile

ZheJiang Mighty Machinery Co. Ltd is a professional manufacturer of auto bearings for more than 20 years. We provide a one-stop service for our customers. Our main products include wheel bearings & hub assembly, belt tensioners, clutch release bearings, and other parts.

Relying on the professional and rich manufacturing experience and many substantial factories which stable cooperated for many years, Mighty suppliers customers high-quality products at very competitive prices.

Customer satisfaction is our First Priority, We adhere to the concept of ” Quality First, Customer First”. We will continue to provide high-quality products and the best services to our customers and build up CZPT long-time friendship partners.

Exhibitions

Our Advantages

More than 20 years of manufacturing and exporting experience

OEM manufacturing available

Full range, large stock

Quickly feedback

One year warranty

One-stop service

On-time delivery

Packaging & Shipping

| Packaging Details | 1 piece in a single box 2 boxes in a carton 30 cartons in a pallet |

| Nearest Port | ZheJiang or HangZhou |

| Lead Time | For stock parts: 1-5 days. If no stock parts: <20 pcs: 15-30 days ≥20 pcs: to be negotiated. |

OUR SERVICES

– We have more than 20 years’ experience in auto bearings fields.

– Excellent quality control is 1 of our main principles

– We offer OEM service, accept customer labels, and develop the product with your drawings or samples

– Any questions will get a response within 24 hours.

FAQ

1. What’s the minimum order quantity?

We don’t have the minimum order quantity. We can also provide free samples, but you need to pay the freight.

2. Do you provide ODM&OEM order service?

Yes, we provide ODM&OEM services to customers around the world, and we can customize different brands and different sizes of packaging boxes according to customers’ requirements.

3. After-sales service and warranty time

We guarantee that our products will be free from defects in materials and workmanship within 12 months from the date of delivery. The warranty is void due to improper use, incorrect installation, and physical damage.

4. How to place an order?

Send us an email of the models, brand, quantity, consignee information, model of transportation, and payment

Confirm payment and arrange the production.

5. What are your packing conditions?

We use standardized export packaging and environmental protection packaging materials. If you have a legally registered patent, we will package the goods in your brand box after receiving your authorization

6. What are your payment terms?

T/T is 30% of the payment in advance and 70% balance before delivery. Before you pay the balance, we will show you photos or videos of the products and packaging.

7. How long is your delivery time?

The delivery time of the sample order is 3-5 days, and that of a batch order is 5-45 days. The exact delivery time depends on the item and the quantity you ordered.

8. Do you test all products before delivery?

Yes, according to ISO standards, we have professional Q/C personnel, precision testing instruments, and an internal inspection system. We control the quality of every process from material receiving to packaging to ensure that you receive high-quality products

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year |

|---|---|

| Warranty: | One Year |

| Type: | Tensioner Bearing |

| Material: | Chrome Steel |

| Tolerance: | P0 |

| Certification: | ISO9001, TS16949 |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the reliability and durability aspects of drive belt tensioners in ensuring consistent tension?

Reliability and durability are crucial aspects of drive belt tensioners in ensuring consistent tension within a vehicle’s belt system. Drive belt tensioners play a vital role in maintaining the proper tension of the drive belt, which is essential for reliable power transmission and preventing belt slippage. Here’s a detailed explanation of the reliability and durability aspects of drive belt tensioners in ensuring consistent tension:

- Material Selection:

- Design and Engineering:

- Load and Tension Capacity:

- Resistance to Environmental Factors:

- Maintenance and Service Life:

The choice of materials used in manufacturing drive belt tensioners significantly impacts their reliability and durability. Tensioners are typically constructed using high-strength materials such as steel, aluminum, or reinforced polymers. These materials provide the necessary strength, rigidity, and resistance to wear and fatigue. The selected materials should be able to withstand the forces and loads experienced during operation without deformation or premature failure, ensuring long-term reliability and consistent tensioning performance.

The design and engineering of drive belt tensioners are critical factors in ensuring their reliability and durability. Tensioners need to be designed to accommodate the specific requirements of the belt system and driven components. This includes considerations such as belt routing, tensioner mounting, and the integration of features like pulleys, bearings, and damping mechanisms. Well-designed tensioners undergo rigorous testing and analysis to ensure they can withstand the anticipated loads, vibrations, temperature variations, and other operating conditions. Proper engineering practices contribute to the longevity and consistent performance of the tensioner throughout its service life.

Reliability and durability of drive belt tensioners are closely linked to their load and tension capacity. Tensioners must be capable of applying and maintaining the proper tension on the drive belt, ensuring it remains properly engaged with the pulleys. The tensioner should be designed with a suitable load capacity to handle the anticipated forces and loads imposed on the belt system during various operating conditions. Adequate load and tension capacity prevent excessive belt deflection, slippage, or premature wear, ensuring consistent tension and reliable power transmission.

Drive belt tensioners are exposed to various environmental factors that can impact their reliability and durability. Factors such as temperature variations, moisture, dirt, and chemical exposure can affect the performance and lifespan of the tensioner. To ensure consistent tension, tensioners are often designed with protective coatings, seals, or materials that offer resistance to these environmental elements. Proper sealing and corrosion-resistant materials minimize the risk of contamination or degradation, ensuring the tensioner’s long-term reliability and consistent tensioning capability.

Regular maintenance and adherence to recommended service intervals are essential for preserving the reliability and durability of drive belt tensioners. Tensioners should be inspected periodically for signs of wear, damage, or misalignment. Proper lubrication of moving parts, such as pulleys and bearings, is also crucial for their longevity and consistent performance. Following the manufacturer’s recommended maintenance procedures and replacing worn or damaged tensioners in a timely manner helps ensure that the tensioner maintains its reliability and consistent tensioning function throughout its expected service life.

In summary, the reliability and durability aspects of drive belt tensioners are crucial in ensuring consistent tension within a vehicle’s belt system. Material selection, design and engineering practices, load and tension capacity, resistance to environmental factors, and proper maintenance all contribute to the reliability and longevity of tensioners. By choosing well-designed and properly maintained tensioners, automotive systems can benefit from consistent belt tension, reliable power transmission, and minimized risks of belt slippage or failure.

What are the common signs of a failing drive belt tensioner, and how can it be diagnosed and addressed?

A failing drive belt tensioner can lead to various issues in the belt system and affect the overall performance and reliability of a vehicle. Recognizing the common signs of a failing tensioner and knowing how to diagnose and address the problem are important for timely repairs and preventing further damage. Here’s a detailed explanation of the common signs of a failing drive belt tensioner and the diagnostic and addressing methods:

- Squealing or Grinding Noises:

- Belt Slippage:

- Visible Wear or Damage:

- Incorrect Belt Tension:

- Tensioner Pulley Misalignment:

One of the most noticeable signs of a failing drive belt tensioner is the presence of squealing or grinding noises coming from the engine area. These noises typically occur when the tensioner pulley or the drive belt is worn out or misaligned. The tensioner may not be applying the proper tension to the belt, causing slippage and generating the noise. If squealing or grinding noises are heard during engine operation, it is recommended to inspect the tensioner and associated components for wear or damage.

A failing tensioner can result in belt slippage, where the belt loses traction and slips on the pulleys. Belt slippage can be observed by a sudden decrease in power delivery to driven components, such as the alternator, power steering pump, or air conditioning compressor. This can lead to reduced functionality of these components and may result in issues like dimming lights, heavy steering, or insufficient cooling. If belt slippage is suspected, a visual inspection of the tensioner and belt system should be performed to identify the cause and address the problem.

Inspecting the drive belt tensioner for visible signs of wear or damage is an important diagnostic step. Common indications of a failing tensioner include cracks, fraying, or glazing on the tensioner pulley or the drive belt. Excessive play or wobbling of the tensioner pulley can also indicate a problem. Additionally, any signs of oil leakage around the tensioner may suggest a failing internal hydraulic mechanism. A thorough visual inspection can help identify the condition of the tensioner and determine if it needs to be replaced.

An improperly tensioned belt can be a result of a failing drive belt tensioner. If the tensioner is unable to maintain the correct tension, the belt may appear loose or too tight. A loose belt can lead to slippage and inadequate power transmission, while an overly tight belt can cause excessive strain on the components and accelerate wear. A belt tension gauge can be used to measure the tension of the belt and compare it to the manufacturer’s specifications. If the tension is outside the recommended range, the tensioner may need to be adjusted or replaced.

Another sign of a failing tensioner is the misalignment of the tensioner pulley. This can be observed by visually inspecting the alignment of the pulley with the other pulleys in the belt system. Misalignment can cause the belt to run at an angle, leading to uneven wear, increased friction, and potential damage to the belt and pulleys. If misalignment is detected, it is important to investigate the cause, which could be a worn tensioner pulley, worn bearings, or a faulty tensioner mounting bracket. Proper realignment or replacement of the affected components may be necessary.

In summary, the common signs of a failing drive belt tensioner include squealing or grinding noises, belt slippage, visible wear or damage, incorrect belt tension, and tensioner pulley misalignment. To diagnose and address the problem, it is recommended to perform a visual inspection of the tensioner and associated components, check for visible wear or damage, measure the belt tension, and assess the alignment of the tensioner pulley. Based on the findings, necessary repairs or replacements of the tensioner or related components can be carried out to ensure the proper functioning of the drive belt system and maintain the performance and reliability of the vehicle.

What is a drive belt tensioner, and how does it contribute to the operation of automotive engines?

A drive belt tensioner is a component used in automotive engines to maintain the proper tension in the drive belt system. It plays a crucial role in ensuring the efficient operation of automotive engines by maintaining the correct tension in the drive belt and facilitating the smooth and reliable transfer of power. Here’s a detailed explanation of what a drive belt tensioner is and how it contributes to the operation of automotive engines:

- Function of a Drive Belt Tensioner:

- Tension Adjustment:

- Prevention of Belt Slippage:

- Reduced Wear and Noise:

- Enhanced System Reliability:

A drive belt tensioner is designed to maintain the optimal tension in the drive belt system of an automotive engine. The drive belt, also known as a serpentine belt, is responsible for transmitting power from the engine’s crankshaft to various components such as the alternator, power steering pump, air conditioning compressor, and water pump. The tensioner ensures that the drive belt is properly tensioned and remains in contact with the pulleys at all times, preventing belt slippage and ensuring the efficient transfer of power.

The drive belt tensioner is equipped with a mechanism that allows for the adjustment of belt tension. It typically consists of a spring-loaded arm or pulley that applies tension to the drive belt. The tensioner is designed to automatically adjust the tension in response to changes in belt length due to wear or temperature variations. This ensures that the drive belt remains properly tensioned throughout its service life, compensating for any stretching or slack that may occur over time.

One of the key contributions of a drive belt tensioner is the prevention of belt slippage. Belt slippage can occur when the drive belt loses contact with the pulleys, resulting in reduced power transfer efficiency and impaired operation of engine accessories. The tensioner maintains the proper tension in the drive belt, ensuring that it remains securely engaged with the pulleys. This prevents slippage, allowing for the efficient operation of engine components and avoiding power loss or potential damage to the belt.

By maintaining the correct tension in the drive belt, the tensioner helps reduce wear on the belt and associated components. Proper tension minimizes excessive movement and vibration of the belt, reducing friction and wear. It also helps to dampen belt vibrations and noise, contributing to a quieter and smoother operation of the automotive engine. Reduced wear and noise levels result in extended belt life and improved reliability of the engine’s accessory components.

The drive belt tensioner plays a critical role in enhancing the reliability of automotive engines. By ensuring the proper tension in the drive belt, it helps prevent belt-related failures and malfunctions. A properly tensioned belt reduces the risk of belt breakage, slippage, or detachment, which can lead to the loss of power to critical engine components. The tensioner contributes to the overall stability and uninterrupted operation of the engine, improving its reliability and reducing the likelihood of unexpected breakdowns or performance issues.

In summary, a drive belt tensioner is an essential component in automotive engines that maintains the proper tension in the drive belt system. It ensures the efficient transfer of power from the engine to various accessories, prevents belt slippage, reduces wear and noise, and enhances the overall reliability of the engine. By properly tensioning the drive belt, the tensioner plays a vital role in the smooth and reliable operation of automotive engines, contributing to their performance, longevity, and optimal functionality.

editor by CX 2024-03-02

China factory Tensor De Chevrolet Nubira 96440419 Auto Alternator Belt Tensioner near me shop

Product Description

Product spections :

| Interchange number: | 9644571 |

| CHEVROLET |

Description :

1. The tensioner is a belt tensioner used in the automobile transmission system. The tension pulley is mainly composed of a fixed shell, a tension arm, a wheel body, a torsion spring, a rolling bearing and a spring sleeve. It can automatically adjust the tension force according to the different tightness of the belt to make the transmission system stable, safe and reliable.

2. The main function of the tensioner bearing is to support the mechanical rotating body.

3.Reduce the friction coefficient during its movement and ensure its rotation accuracy.

4.Change sliding friction into rolling friction.

| Chevrolet | Nubira | 2011 | Diesel Estate | 2.0 D | 1991cc 89KW 121HP LMN |

| Chevrolet | Nubira | 2011 | Diesel Saloon | 2.0 D | 1991cc 89KW 121HP LMN |

| Chevrolet | Nubira | 2571 | Diesel Estate | 2.0 D | 1991cc 89KW 121HP LMN |

| Chevrolet | Nubira | 2571 | Diesel Saloon | 2.0 D | 1991cc 89KW 121HP LMN |

| Chevrolet | Nubira | 2009 | Diesel Estate | 2.0 D | 1991cc 89KW 121HP LMN |

| Chevrolet | Nubira | 2009 | Diesel Saloon | 2.0 D | 1991cc 89KW 121HP LMN |

| Chevrolet | Nubira | 2008 | Diesel Estate | 2.0 D | 1991cc 89KW 121HP LMN |

| Chevrolet | Nubira | 2008 | Diesel Saloon | 2.0 D | 1991cc 89KW 121HP LMN |

| Chevrolet | Nubira | 2007 | Diesel Estate | 2.0 D | 1991cc 89KW 121HP LMN |

| Chevrolet | Nubira | 2007 | Diesel Saloon | 2.0 D | 1991cc 89KW 121HP LMN |

| Chevrolet | Nubira | 2006 | Diesel Saloon | 2.0 D | 1991cc 89KW 121HP LMN |

| Chevrolet | Nubira | 2005 | Diesel Saloon | 2.0 D | 1991cc 89KW 121HP LMN |

| Vauxhall | Antara | 2015 | Diesel SUV | 2.0 CDTI | 1991cc 110KW 150HP Z 20 DMH |

| Vauxhall | Antara | 2014 | Diesel SUV | 2.0 CDTI | 1991cc 110KW 150HP Z 20 DMH |

| Vauxhall | Antara | 2013 | Diesel SUV | 2.0 CDTI | 1991cc 110KW 150HP Z 20 DMH |

| Vauxhall | Antara | 2012 | Diesel SUV | 2.0 CDTI | 1991cc 110KW 150HP Z 20 DMH |

| Vauxhall | Antara | 2011 | Diesel SUV | 2.0 CDTI | 1991cc 110KW 150HP Z 20 DMH |

| Vauxhall | Antara | 2571 | Diesel SUV | 2.0 CDTI | 1991cc 110KW 150HP Z 20 DMH |

| Vauxhall | Antara | 2009 | Diesel SUV | 2.0 CDTI | 1991cc 110KW 150HP Z 20 DMH |

| Vauxhall | Antara | 2008 | Diesel SUV | 2.0 CDTI | 1991cc 110KW 150HP Z 20 DMH |

| Vauxhall | Antara | 2007 | Diesel SUV | 2.0 CDTI | 1991cc 110KW 150HP Z 20 DMH |

| Vauxhall | Antara | 2006 | Diesel SUV | 2.0 CDTI | 1991cc 110KW 150HP Z 20 DMH |

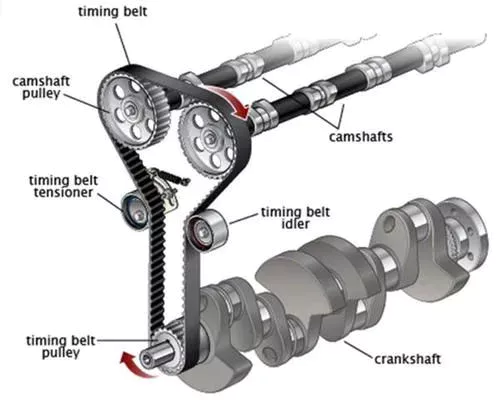

How to Prevent Timing Belt Problems

Unlike their predecessors, timing chains and timing belts are made of rubber and synchronize the opening and closing of valves in the engine. While their benefits are numerous, they are prone to wear and tear over time. Here are some tips for ensuring your timing belt lasts for many years. Listed below are some of the most common problems that you may encounter when changing your timing belt. Read on to find out how to prevent them and keep your car running at peak performance.

Timing belts are rubber

There are many advantages to using timing belts in your car. They are lightweight and reduce the strain on your vehicle’s internal components. They are also quiet when running, so you won’t have to listen to your car to know that maintenance is needed. If you’re concerned about noise, a quiet engine can help you determine whether your timing belts are broken or if you need to replace them altogether. A quiet engine can also help you notice signs of wear and tear before you do.

Regardless of material, rubber timing belts can be susceptible to stretching and breaking. They also are susceptible to high temperatures and the lubrication of motor oil, reducing their lifespan. Manufacturers have responded to this problem by creating timing belts made of engine-temperature-resistant rubber materials. The improved rubber compounds also provide greater strength and resistance to distortion. Reinforcing fibers also protect the teeth from shearing, reducing the risk of a worn-out timing belt.

While the open-ended, or spliced, types of timing belts have many advantages, they are generally unsuitable for high-speed applications. In most cases, rubber timing belts are used in high-speed machine tools and automatic doors. They are also quiet and require minimal maintenance. These characteristics make rubber timing belts a great choice for high-speed applications. You can even order custom-made timing belts for unusual applications.

Timing belts are important for the functioning of an engine. They link the camshaft and crankshaft to the crankshaft. They control the movement of valves and pistons. If a timing belt fails, it can cause major damage to the engine. If you are unsure of the benefits of rubber timing belts, consider a video on the topic. This will provide you with more information on timing belts.

They synchronize the opening and closing of the engine’s valves

During the combustion process of the engine, the valves in the cylinder head open and close. Fresh air enters the cylinder, which burns with the fuel to generate power. Exhaust escapes the engine through the exhaust valve. Each cylinder contains between 2 and 4 valves. The timing belt drives a camshaft, which rotates in a precise manner to synchronize the valve opening and closing.

A timing belt is a toothed rubber belt that connects the engine’s crankshaft to the crankshaft. Like most rubber parts, timing belts degrade over time, so it’s important to replace them at the proper intervals. Replacement intervals vary depending on the make and model of the vehicle, but they should be replaced every 60 to 90 thousand miles.

A broken timing belt will not start the engine. A timing belt driven vehicle will need to be towed to a repair shop for repairs. In the automotive industry, timing belts drive both “free running” and “interference” engines. The timing belt transfers the crankshaft’s rotation to the camshafts, which in turn actuate the valves in the intake and exhaust system. When they malfunction, the pistons can contact open valves, bending or punching them.

Timing belts also work with pistons and connecting rods to create power. Perfect timing is essential for the engine to run smoothly. The timing belt regulates both the pistons and the valves. If they are out of sync, they may not ignite properly, leading to catastrophic engine failure. When you’re looking for a replacement, look for these signs of wear.

They are lighter, quieter and more efficient than timing chains

While the initial choice was for quieter performance, variable timing has led to greater efficiency and power. While noise is a factor, the average consumer cannot tell the difference. And while timing belts are generally lighter and quieter, a chain can be more noisy than a belt, which can cause more engine damage. If you’re unsure whether you should opt for a chain or a belt, consult your owner’s manual.

A timing chain functions similar to a timing belt but is made from metal and is housed inside the engine compartment. It receives its lubrication from engine oil. Timing chains can last a long time as long as you keep them properly maintained. A timing chain is not as efficient as a timing belt, but it is more accurate, quieter and easier to maintain.

A timing belt uses teeth to time the movement of various components in an engine. When the timing belt is broken, the valves in the engine will not be in sync, leading to a loss of pressure in the combustion chamber. This can cause a plethora of engine problems and cost-increasing repairs. A timing belt is also quieter and requires less lubrication, so it is safer and quieter than a timing chain.

After the advent of variable valve timing, cars began to use a timing chain. This design improved engine performance and reduced maintenance, but it also caused a backlash as consumers were no longer interested in this kind of routine maintenance. Today, however, timing chains are making a comeback in the automotive industry. While modern chains can still be noisy, they are easier to maintain, are lighter, and last longer than their chain counterparts.

They wear out over time

Even the best drive belts will eventually wear out. The main causes of belt wear include mileage and heat. The belt bends as it passes the pulley, producing heat that hardens the rubber. When the belt slips, it increases friction, accelerating the process. A worn-out belt can be very difficult to start, causing an engine to lose fuel efficiency. To help prevent this problem, check the belt for wear and tear.

A timing belt is an engine component that connects the camshaft to the crankshaft and controls the timing of combustion. These belts are made of industrial-strength rubber, and often contain nylon-reinforced cords. Although they are meant to last, they will eventually wear out. If the timing belt fails, your engine won’t run smoothly or you could spend thousands of dollars fixing it.

A faulty timing belt can cause the valves to open too early or too late, causing poor combustion and a drop in engine performance. If the timing belt breaks, the valves may hit the pistons and cause damage. This can lead to engine breakage, which requires a new engine. To prevent this, you should replace the timing belt every couple of thousand miles. If you can’t find a reliable mechanic, it is best to seek professional help from a reputable mechanic.

Another warning sign that your timing belt needs replacing is a ticking sound coming from within your engine. This is an indication of a lower oil pressure than normal. Low oil pressure can affect the timing belt as it can cause the tensioner that holds the belt taut will lose pressure. Eventually, the belt may even break, allowing the camshafts to slip and break. Once this happens, it is time to replace the timing belt.

They can be repaired

Timing belts can be repaired. If your timing belt breaks, you can take your car to a repair shop to have it repaired or replaced. The price of a repair depends on the labor hours and how many hours it takes to do the job. A bad timing belt can ruin your engine and cause it to break down completely. If you’re unable to drive your vehicle, it may require towing and a new engine.

For most drivers, a timing belt replacement will cost about $1,000 at a dealership. Luckily, you can often get the same service for less at an independent auto repair shop. Often, a timing belt repair requires replacing the water pump, too. It makes sense to replace both at the same time. But remember that timing belts are more complicated than that. If you’re worried about the cost, you can replace the water pump along with the timing belt.

If you’re in the mood to do this repair, there are many companies that offer this service. The cost is relatively low and you’ll probably save hundreds of dollars over the course of the job. However, timing belt repair is not a simple job and must be done correctly or you could end up damaging your car engine. Therefore, it’s important to know how to repair a timing belt yourself to avoid the high price of hiring a mechanic.

When timing belts start to fail, there are a few warning signs you can listen for. A difficult start-up can be a sign that your belt needs to be replaced. Also, thick smoke coming from the tailpipe can be a sign that the timing belt needs to be changed. In addition to these symptoms, your timing belt may have a crack or broken gear teeth, which means it needs to be replaced.

China manufacturer Yuejin Truck 1E11010548 CZPT Sofim 97301821 Alternator Belt Tensioner with Hot selling

Product Description

Yuejin truck 1E11571548 CZPT Sofim 97301821 alternator belt tensioner,; with yuejin spare part list as:;

| Model | Description | Yuejin Part Number | Iveco Part Number | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8140.;43 | Cooling fan | 1D5711070 | 97211844 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8140.;43 | Clutch release bearing | 1D571170 | 97260176 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8140.;43 | Clutch disc | 1D07040460 | 97260181 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8140.;43 | Clutch cover | 1D 0571 11 | 9726 0571 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8140.;43 | Charging alternator | 1E1016571 | 97280443 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8140.;43 | Power steering pump | 1D 0571 0120 | 9730571 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8140.;43 | Turbocharger | 1D 0571 15 Website:;hantonmachinery.;en.;made-in-china.;com

What to Look for in a Belt TensionerIf you notice the power steering, air conditioning, or power steering stops working, chances are that your belt tensioner has been compromised. A compromised belt tensioner can be completely destroyed overnight, or it can last for a long time before it breaks. Either way, you should never drive with a faulty belt tensioner. It’s far better to have it replaced before the engine shuts down completely. In addition, replacing a belt tensioner will prevent other complications, such as power steering or air conditioning, from occurring. Misaligned idler pulleyIf the tensioner arm is not rotating freely or has an abnormal chirping noise, it could be the result of a misaligned idler pulley. If this is the case, replace the idler. If the idler does not move, you may need to adjust the accessory mount points or use a laser alignment tool. The tensioner arm is only 1 part of the tensioner. Bad idler pulleyHaving a Bad Idler Pulley on a Belt Tensioner? If this sounds familiar, then it’s probably time to change it. Idler pulleys slowly take hits while the engine is running, causing the belt to wrap and bend. Eventually, the belt will slip, and a new idler pulley should be installed to ensure optimal tension. But before you spend a dime on a new one, let’s talk about what to look for. Broken tensioner armThe belt tensioner is a piece of machinery that is used to keep the belt tight. If this part breaks, you can easily repair it yourself using a long-handled ratchet, serpentine belt tool, or a socket. To repair the tensioner, simply remove the drive belt from the pulley and rotate it to release tension. Check for roughness, resistance, or binding of the drive belt.

China Best Sales Alternator Belt Tensioner Assembly 11955et00A 11955jd21A Vkm62025 for CZPT Yaris with Best Sales

Product Description

Quick view:

ZheJiang Mighty (SI Bearing)are providing deep groove ball bearing, tapered roller bearing, pillow block bearing, spherical roller bearing, angular contact ball bearing, needle bearing, self-aligning ball bearing, linear bearing, wheel hub bearing, hub unit, clutch release bearing, belt tensioner, etc. Our Bearing Advantage: FAQ: Q: How can I make an inquiry? Q: How long can reply inquiry? A: Within 24 hours. Q: Which Service you can provide? Q: When are you going to deliver? Q: What’s your delivery way? Q: What are your terms of delivery? Q: Can you support the sample order? Q: What are you going to do if there has a claim for the quality or quantity missing?

Types of V-Belt DrivesWhen evaluating drive technologies, you might want to consider a V-Belt. Not only can it improve the performance of an older drive, but it can save you time and money in the long run. Industry standard V-belts are prone to failing because of excessive wear, heat cracks, and stretching. Inefficient and downtime resulting from frequent retensioning and replacement can cost your company both time and money. Cross-A cross-belt for a V-Belt is a belt that is used in a conveyor system. This belt consists of 2 parts: an elastomer core and a fabric cover. The elastomer core is typically made of high-shock-resistant polyurethane. Different manufacturers have different synthetic rubber stocks, which may be used to prevent premature failure and extend the operating temperature range of the belt. Ideally, a well-engineered V-belt is stiff in the width and flexible along the length of the belt. The fabric covers are generally made of 2 different types of rubber, including compression and cushion rubber. U-shapedThe V-belt is a versatile belt used in countless industrial applications. Advancements in engineering have led to many different types of V-belts. Whether it’s a U-shaped belt or a double-sided V-belt, proper installation and maintenance are crucial for trouble-free operation. Below are some common V-belt specifications. Read on to learn more! The U-shaped V-belt is 1 of the most common. CoggedThere are many advantages of a Cogged V-Belt. Its extra-thick construction allows for bends around smaller pulleys. It also runs cooler and lasts longer than a traditional V-belt. In addition, it has a higher coefficient of friction than a wrapped V-belt. Cogged V-Belts can also resist heat, making them an excellent choice for high-temperature applications. WedgeThe Wedge V-Belt is 1 of the most popular types of drive belts available. The patented, narrow-profile design allows for lighter, thinner belts with greater transmission capabilities. The HY-T V-Belt is constructed with Vytacord tension members for strength and dimensional stability, and includes a cushion made of engineered rubber compound. This belt is ideal for high-speed, high-resistance applications, such as compressors, stone mills, and centrifugal pumps.

China supplier Alternator Belt Tensioner 8149855 Tensioner for Renault Tractor Trucks and CZPT for CZPT D12 Engine 20966526 with high quality

Product Description

Product spections :

Description : 1. The tensioner is a belt tensioner used in the automobile transmission system. The tension pulley is mainly composed of a fixed shell, a tension arm, a wheel body, a torsion spring, a rolling bearing and a spring sleeve. It can automatically adjust the tension force according to the different tightness of the belt to make the transmission system stable, safe and reliable. 2. The main function of the tensioner bearing is to support the mechanical rotating body. 3.Reduce the friction coefficient during its movement and ensure its rotation accuracy. 4.Change sliding friction into rolling friction.

Tips For Replacing a Belt TensionerWhen replacing a serpentine belt or automatic tensioner, you will need a special tool. This tool has a long, flat extension handle that allows you to place a socket onto the bolt and flats on the tensioner arm. The following are some tips to follow when replacing the belt or tensioner on your vehicle. To replace your belt or tensioner, you should start by checking the tensioner’s lubrication. Serpentine beltIf you notice that the power steering or air conditioning are not working, you should check the serpentine belt tensioner. A malfunctioning serpentine belt tensioner can lead to a host of other issues. The belt may stretch, which can be caused by several factors. Over time, serpentine belt tensioners can also get worn down. Additionally, they can have a variety of other problems, including rust or dirt in the housing. Idler pulleyThe idler pulley and the belt tensioner are essential components of your car’s drivetrain. If any 1 of them fails, all of them must be replaced. This is because they were manufactured at the same time and most likely have the same number of miles on them. As a result, they can all fail within a few thousand miles of each other. Here are some of the symptoms that you should look for when inspecting your idler pulley or belt tensioner. Spring tensionerA spring belt tensioner is a solution to a loose belt. It features a strong torsion spring that reduces slack. These devices are designed to fit up to 6mm wide belts. They are highly reliable and durable. They are also suitable for applications where the engine speed is often fluctuating. Here’s how you can choose the best 1 for your vehicle. The spring in the tensioner should be in the proper position to keep the belt taut and free of slippage.

|